At Ruike Petrochemical, we engineer advanced Wiped Film Evaporators (WFE) designed to tackle your most challenging separation tasks. Whether you are processing re-refined oil, stripping solvents, or purifying chemical intermediates, our systems deliver low residence time and high heat transfer efficiency—ensuring your product quality remains uncompromised.

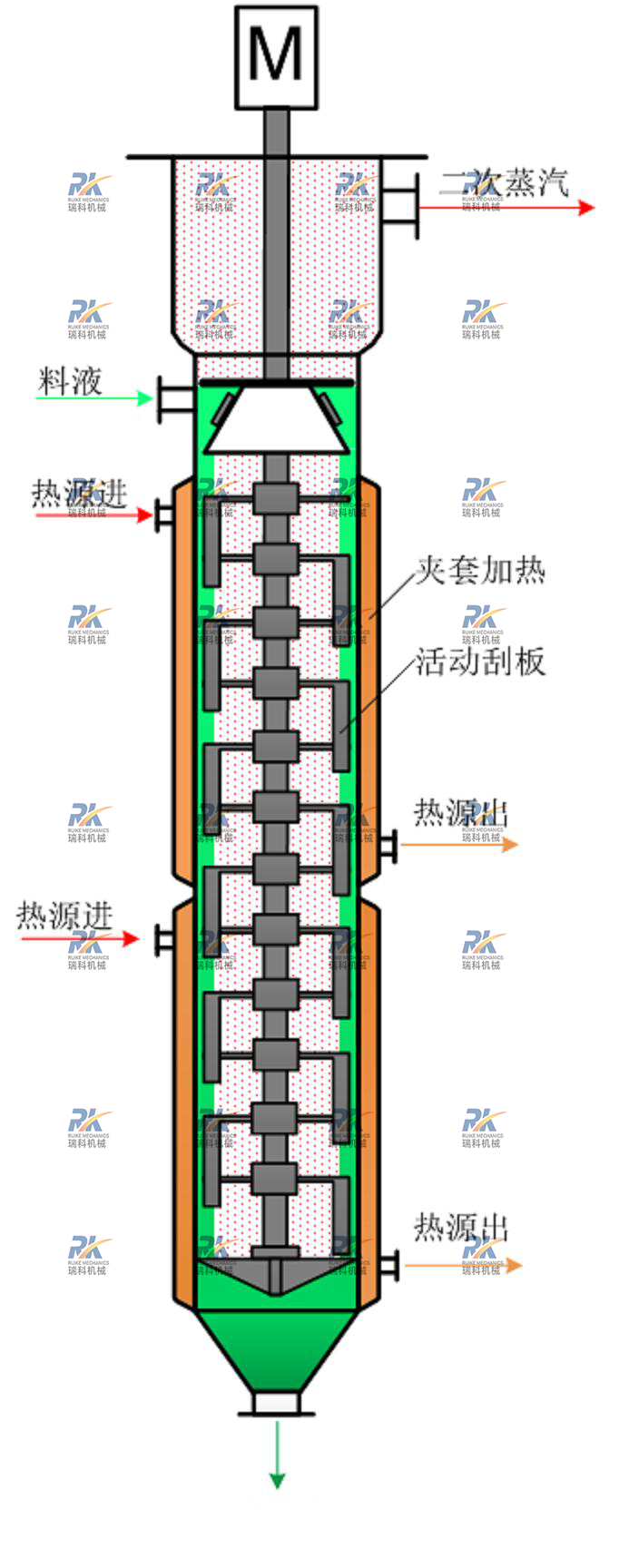

Motor + Reducer: Precision control of scraper blade rotation speed (5-300 rpm adjustable)

Gas-Liquid Separator: High-efficiency droplet capture. Bottom Head: Allows rapid discharge of high-temperature residues.

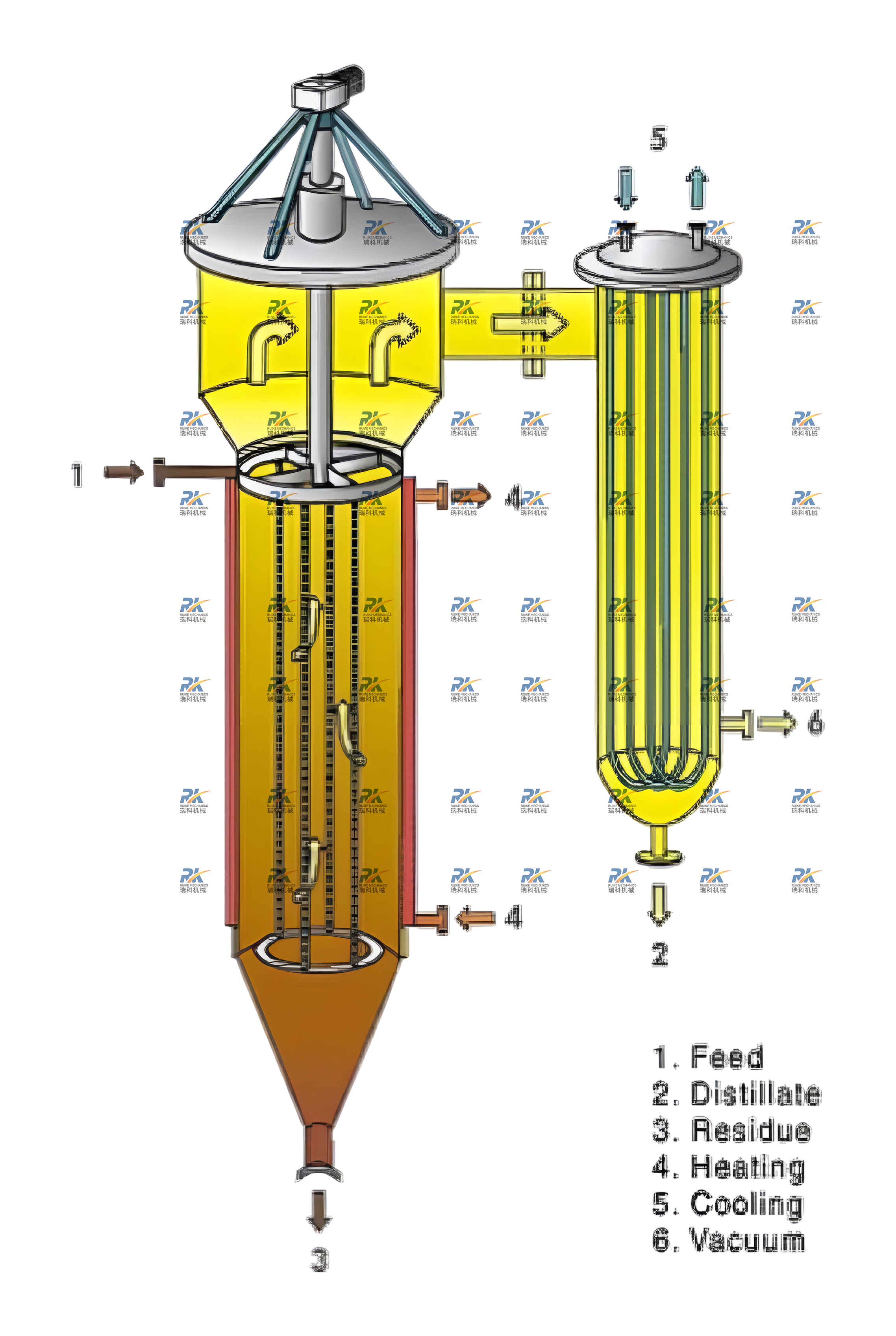

Liquid feed enters above the heated zone and is distributed evenly.

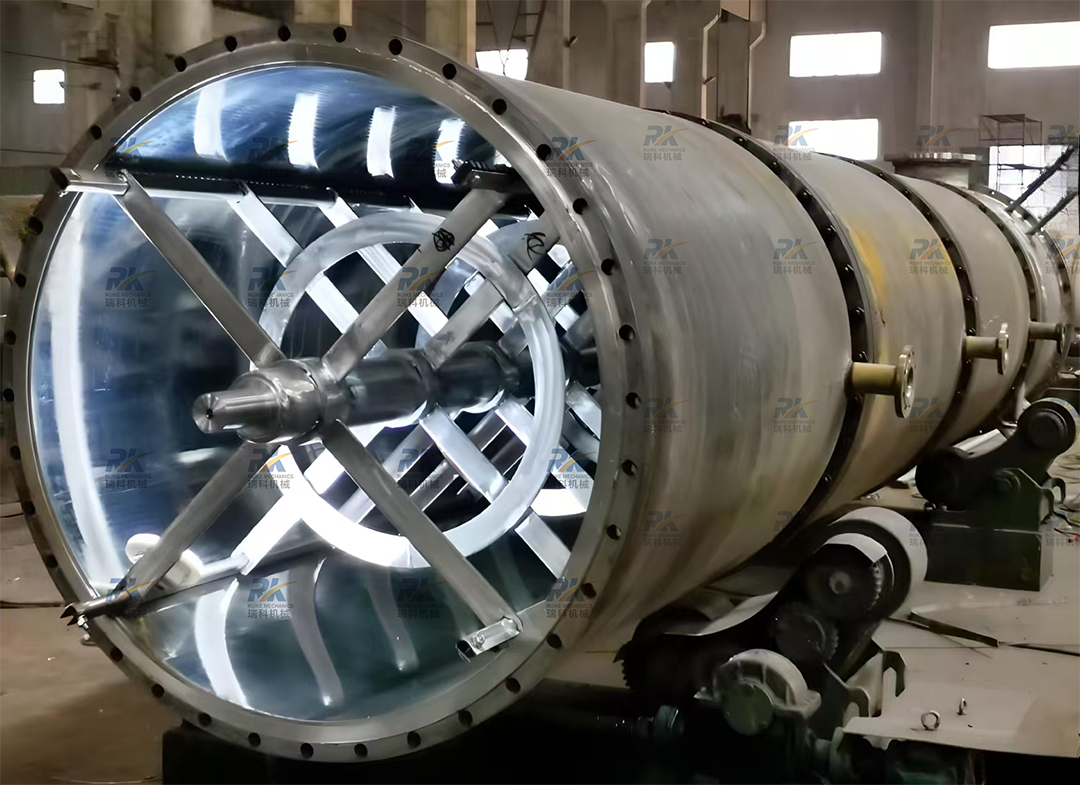

Rotating wiper blades spread the liquid against the heated inner wall, creating a highly turbulent thin film.

Volatile components evaporate instantly and travel to the condenser.

The concentrated heavy fraction flows down the wall and is discharged at the bottom with minimal holdup.

Seamless Integration into Your Continuous Production Line

A Wiped Film Evaporator (WFE) is rarely a standalone unit; it is the heart of a sophisticated separation stage. At Ruike Petrochemical, we design our systems to integrate flawlessly into existing petrochemical workflows, optimizing mass transfer and thermal efficiency from feed to discharge.

Here is a breakdown of the typical continuous processing loop using Ruike technology:

The Preparation Stage: Raw material (such as waste lube oil, crude chemical intermediates, or polymer melts) is first pumped through a filtration system to remove solid particulates.

Degassing: Before entering the main evaporator, the feed often passes through a degassing stage to remove light volatiles (water, air, light solvents).

Pre-heating: The feed is brought close to the boiling point to maximize the efficiency of the WFE’s surface area immediately upon entry.

The Critical Separation Stage: The pre-heated fluid enters the Wiped Film Evaporator under high vacuum conditions.

Mechanical Distribution: Our precision rotors spread the fluid into a thin, turbulent film (0.1–0.5 mm thick).

Vapor-Liquid Separation: Heat is applied through the jacket. The turbulent film ensures rapid heat transfer, causing the target volatile component to evaporate instantly while heavier residues flow downwards.

Prevention of Fouling: Because the wiper blades are continuously agitating the film, “burn-on” or surface fouling—common in petrochemical processing—is virtually eliminated.

The Product Collection Stage: The evaporated vapors travel to a condenser (either internal or external, depending on the specific model and vacuum requirements).

Efficiency: The vapors are condensed back into liquid form and discharged continuously as the Distillate (e.g., purified base oil or recovered solvent).

Vacuum System: A robust vacuum pump system maintains the pressure differential, ensuring the boiling point remains low to protect the product.

The Bottoms Handling Stage: The heavier components that did not evaporate flow down the heated wall to the bottom discharge cone.

Continuous Output: The Residue (e.g., asphalt/bitumen extenders or heavy polymers) is pumped out continuously without breaking the vacuum.

Secondary Pass: For complex mixtures, the residue can be re-routed to a second WFE stage for further stripping, maximizing overall yield.

Rotating Scraper + Vacuum Synergy: 0.1-1mm liquid film thickness, 50%+ boiling point reduction

Column-Equipment-Tank Three-Stage Control: Gasoline/diesel fraction entrainment <0.01%

Dual Reflux Technology: Intermediate draw temperature fluctuation ≤±2℃

Bottom Head Direct Discharge Design: Residue residence time <10 seconds, prevents secondary coking

Custom configurations are available to meet your specific throughput and material requirements.

Feature | Specification Range |

Evaporation Area | 0.1 m² to 50 m² (Lab to Industrial Scale) |

Operating Temperature | Up to 350°C (Thermal Oil / Steam) |

Operating Pressure | Atmospheric down to 0.1 Pa (High Vacuum) |

Material of Construction | SS304, SS316L, Titanium, Hastelloy (Optional) |

Viscosity Range | Up to 100,000 cP |

Heating Method | Jacketed for Steam or Thermal Oil |

Consult with our technical engineers today to determine the right Wiped Film Evaporator configuration for your project.

Traditional evaporation methods often fail when handling high-viscosity fluids or thermally unstable compounds. Our Agitated Thin Film Evaporator technology solves these issues by mechanically generating a thin, turbulent film.

The extremely short residence time (seconds) protects heat-sensitive components from decomposition.

Our precision-engineered wiper blades effectively process materials with viscosity up to 100,000 cP, preventing fouling and buildup on heat transfer surfaces.

Operate at deep vacuum levels to significantly lower boiling points, ideal for high-boiling petrochemical fractions.

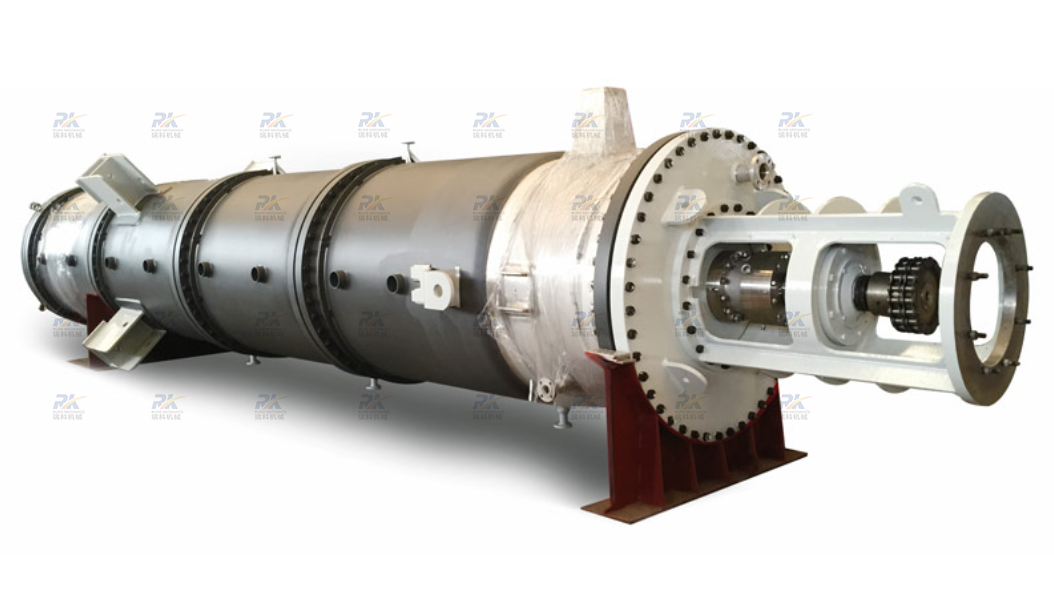

Designed for 24/7 industrial use with robust mechanical seals and reliable drive systems.

We are not just an equipment supplier; we are your process optimization partner.

Factory Direct: Direct manufacturing ensures competitive pricing and quality control.

Customization: We tailor the rotor type (fixed clearance, hinged, or rolled) to your specific material properties.

Global Standard: Our pressure vessels comply with ASME and PED standards upon request.

we take a personalized approach to provide tailored solutions that align perfectly with your specific requirements.