We offer a wide range of high-quality equipment and solutions for petrochemical industries.

Ruike includes specialized plants equipped with the most advanced equipment and modern control facilities.

Our technology team offers customized technical proposal as different raw oil and production requirements.

We provide on-site installation guidance, worker training, and lifetime technical support.

Founded with a vision to innovate waste-to-energy technology, Ruike Petrochemical has spent 19 years perfecting the art of resource recovery.

Unlike standard trading companies, we are a manufacturer that provides end-to-end customized solutions—from engineering design and manufacturing to on-site installation and commissioning.

Whether you need a 1-ton skid-mounted unit for pilot testing or a 200-ton industrial refinery plant, our engineers tailor every specification to meet your local environmental regulations and capacity demands.

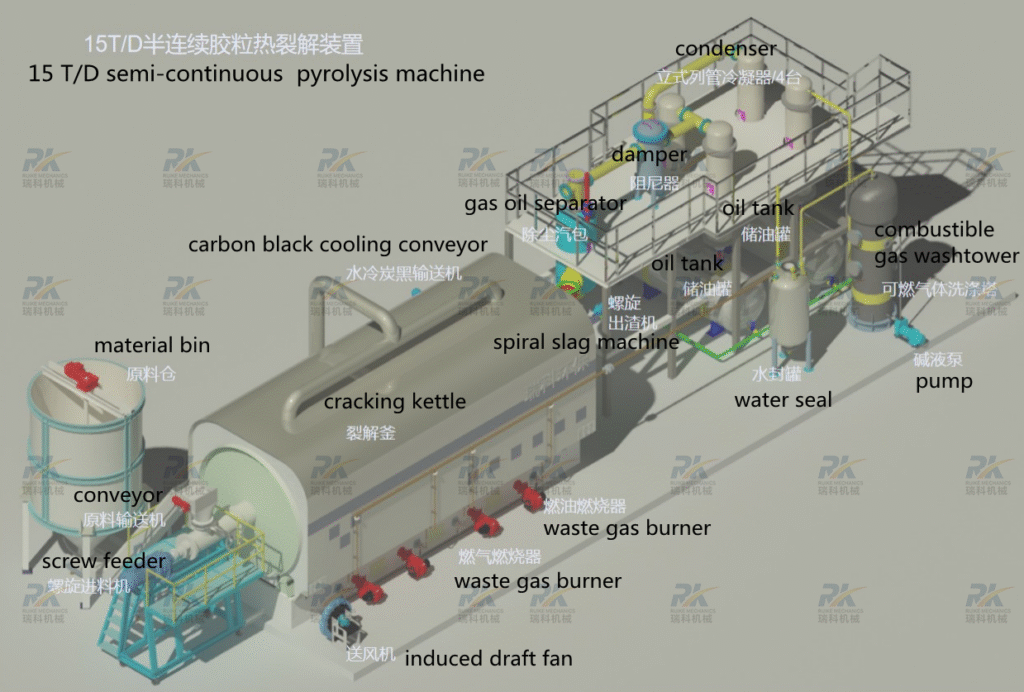

convert scrap tires and plastics into valuable fuel oil, carbon black, and steel wire with our zero-pollution pyrolysis systems. We offer batch, semi-continuous, and fully continuous plants to match your processing volume.

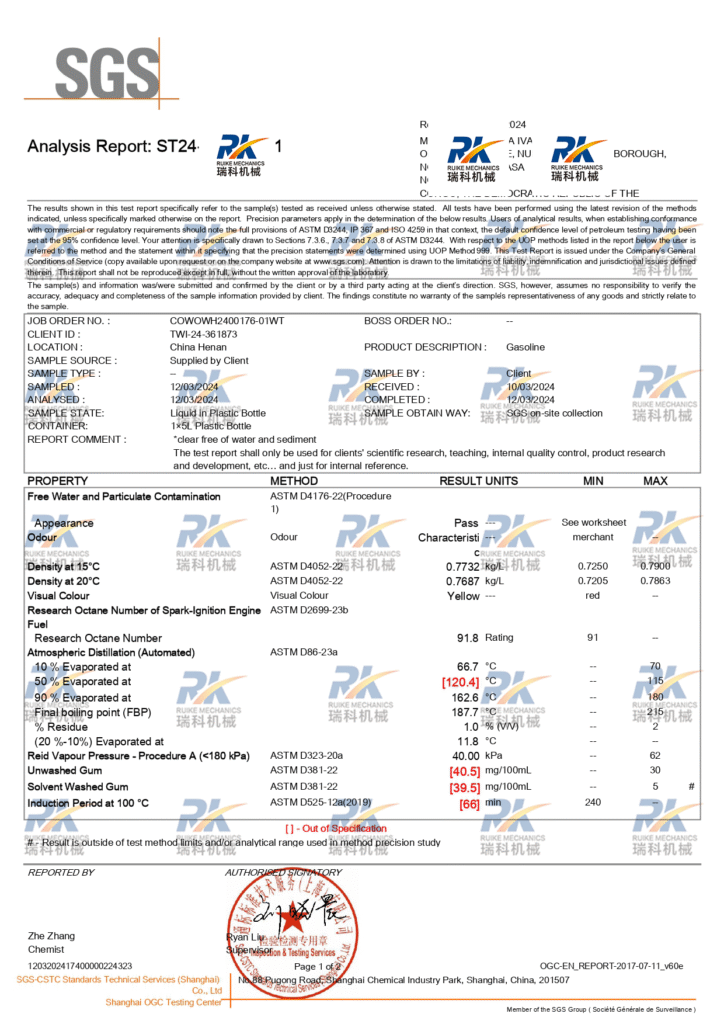

Refine used engine oil, crude oil, or pyrolysis oil into high-quality diesel or base oil. Our proprietary catalytic technology and wiped film evaporators ensure a high yield and SGS-verified oil quality.

Our experienced engineers provide EPC (Engineering, Procurement, and Construction) services for complex refinery projects, including naphtha-to-gasoline conversion and customized crude oil distillation units.

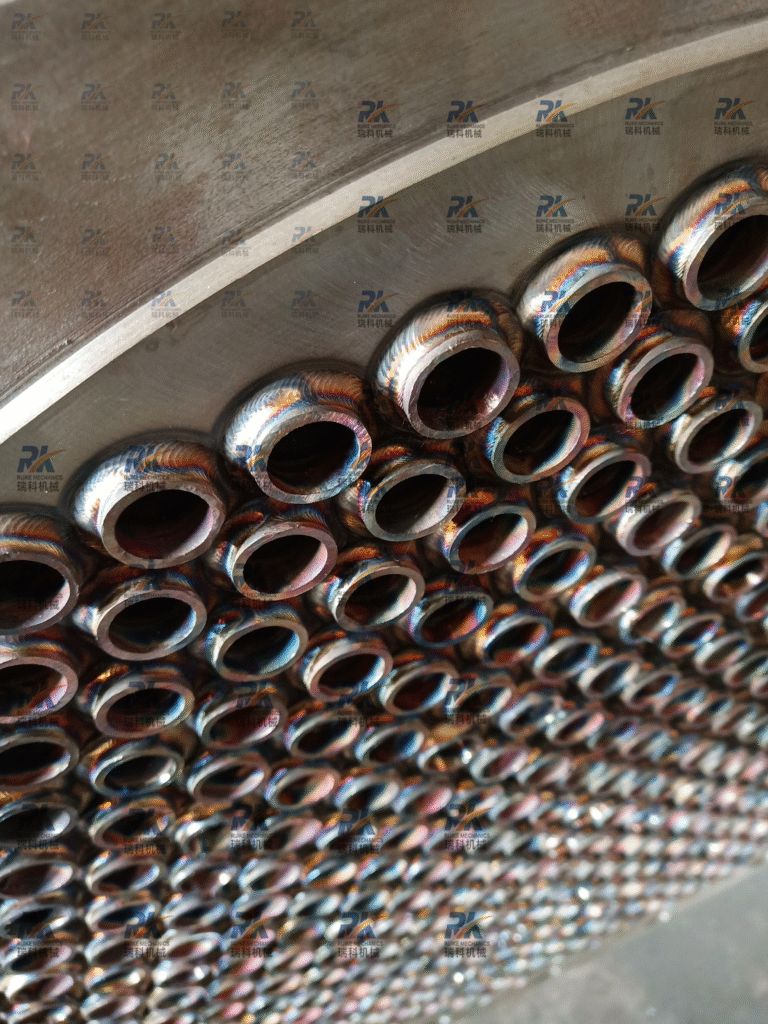

We provide precision fabrication services for custom machinery components. Our team can manufacture to your exact drawings and specifications. Like ASME-certified pressure vessels, reactors, and heat exchangers.

SPECIALIZED INDUSTRIAL ENGINEERING, MANUFACTURING, CONSTRUCTION, SERVICE.

Ruike is a specialty engineering, fabrication, construction, and services company delivering end-to-end project solutions across a broad array of industries.

We have successfully installed projects in the US, UK, Malaysia, Uzbekistan, South Africa, Korea, Singapore, and beyond.

Also operating in: Indonesia (150T Distillation), Myanmar (50T Refinery), Malaysia (30T Crude Distillation), and more.

Project: 50-Ton Used Engine Oil Distillation Plant

Meeting strict US environmental & emission standards.

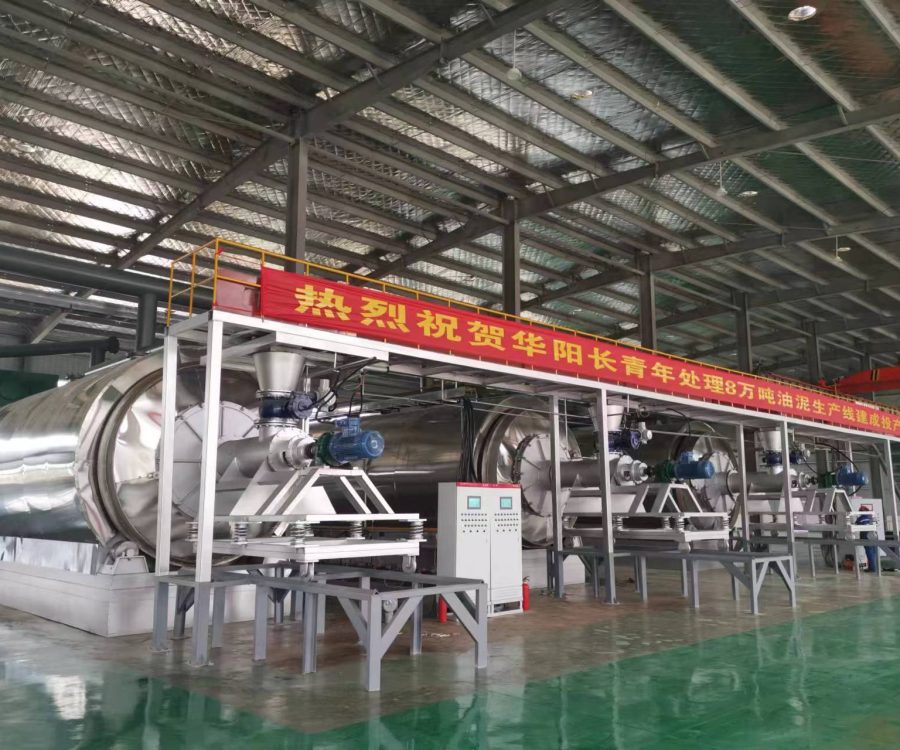

Project: 4 Sets of Pyrolysis Machines for Oil Sludge Recycling

Stainless steel material and continuous operation.

Project: 3-Ton Waste Plastic Pyrolysis to Diesel Plant

High-precision engineering for plastic-to-fuel conversion.

Project: 200-Ton Used Oil to Base Oil Distillation Plant

Large-scale industrial capacity with premium-quality output.

Project: 100-Ton Naphtha to 93# Gasoline Project

Advanced petrochemical process engineering.

With 19 years of expertise, we fabricate and assemble full-scale pyrolysis and distillation plants, ensuring seamless integration and operational efficiency for projects of any size.

Need a specific part? We offer OEM services for reactors, heat exchangers, and pressure vessels, manufacturing strictly according to your technical drawings and material specifications.

Our factory is equipped with cutting-edge CNC machining, automated welding robots, and large-scale rolling machines, capable of processing Carbon Steel, Stainless Steel, and high-performance alloys.

We maintain an uncompromising commitment to quality. Every unit and component undergoes rigorous NDT (Non-Destructive Testing) and pressure testing before leaving our workshop.

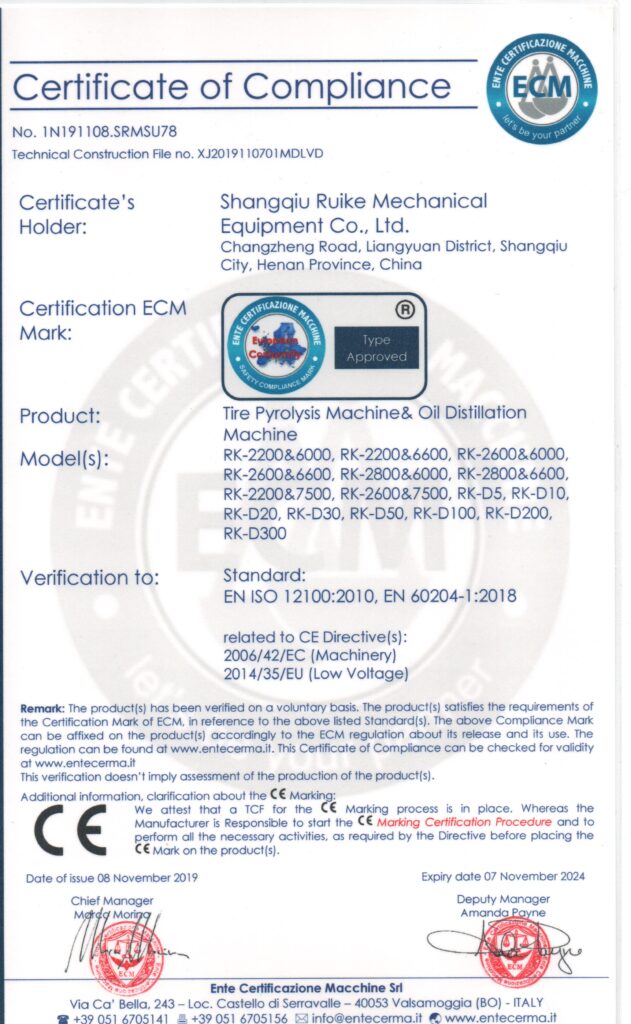

ASME & CE Certified Quality: Our pressure vessels adhere to the highest international safety and quality standards, ensuring operational reliability and a long service life.

Customized Engineering: From 1-ton skid-mounted units to 200-ton industrial refineries, our engineers design solutions tailored to your specific feedstock, capacity, and local environmental regulations.

End-to-End Project Partnership: We are not just a manufacturer; we are your project partner. We provide comprehensive support including on-site installation guidance, operator training, and lifetime technical assistance.

Proven Global Track Record: With successful projects in over 78 countries, including the USA, UK, and South Korea, our technology is tested and trusted by clients worldwide.

We don’t just talk about quality, we prove it. Our manufacturing processes and products are independently verified to meet the most stringent international standards for safety, reliability, and environmental compliance. This assures you that you are investing in equipment designed for long-term performance and reliability.

Frequently Asked Questions About Ruike Petrochemical Equipment Manufacturing Co.

Contact our engineers today for a free project feasibility analysis and quotation.

We will reply within 24 hours

Yes, absolutely. Ruike provides turnkey support globally. We dispatch experienced engineers to your site to guide the installation, commission the plant, and train your local workers until the machine runs smoothly. For smaller units (like skid-mounted plants), we also offer detailed 3D installation videos and remote support.

Yes. Our manufacturing adheres to ASME (American Society of Mechanical Engineers) and CE standards. We design our plants with advanced dedusting and desulfurization systems to meet strict emission regulations in Europe and North America.

The yield depends on the raw material. Generally, waste tires yield 45%-50% fuel oil. For plastics, the yield varies from 30% to 90% (PP/PE/PS have high yields). Contact us for a detailed material analysis report.

Yes. We are a manufacturer, not a trading company. We can customize solutions ranging from 500kg skid-mounted testing units to 50+ ton continuous industrial plants. Our engineers will design the layout based on your available land area.

Typically, manufacturing takes 20-35 working days for standard models. For customized or large-scale refinery lines, the timeline will be specified in the contract. We ensure strict quality control throughout the process.

we take a personalized approach to provide tailored solutions that align perfectly with your specific requirements.