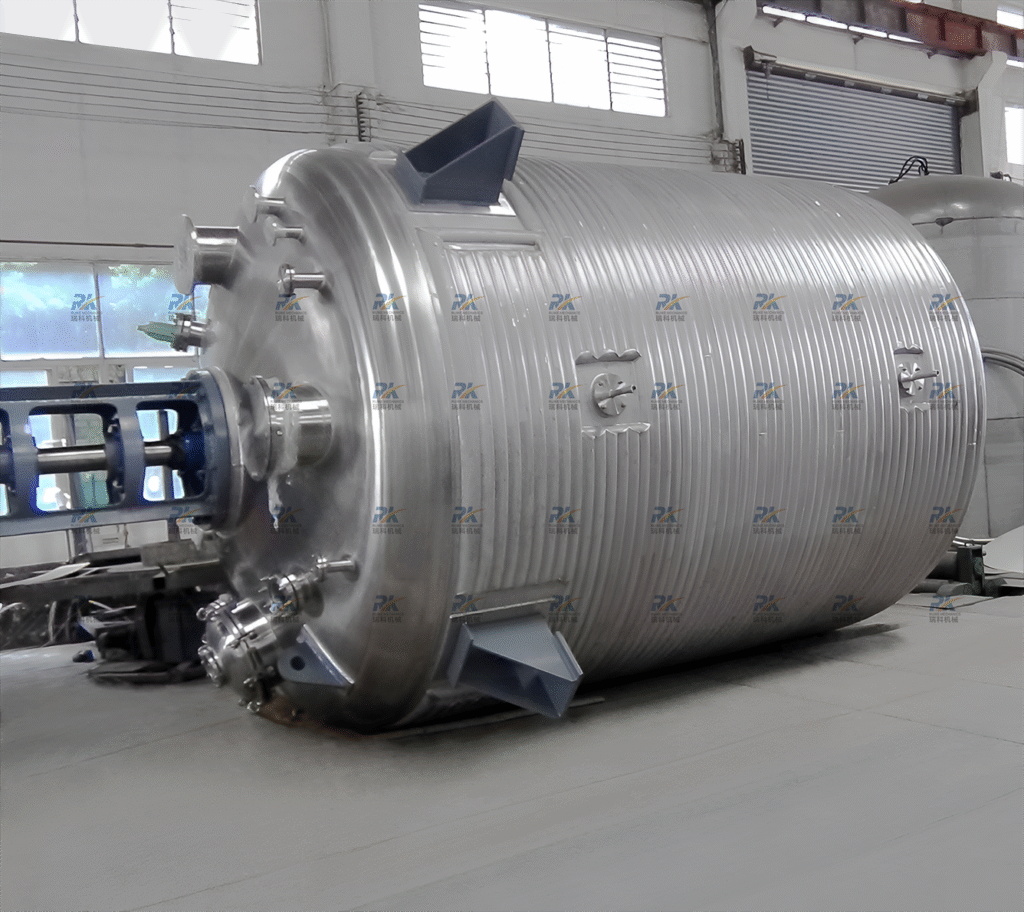

Industrial Stainless Steel Reactors & Mixing Vessels for Petrochemical

Engineered for high-pressure, high-temperature, and corrosive environments. Custom-fabricated from 50L to 32,000L to meet your exact process requirements.

With over 17 years of expertise, Ruike Petrochemical is a premier manufacturer of heavy-duty stainless steel reactors. We specialize in delivering turnkey reaction solutions for the oil refining, chemical synthesis, and pharmaceutical industries globally. Whether you require a standard batch reactor or a bespoke continuous processing vessel, our engineering team ensures ASME-grade quality, strict compliance with international safety standards, and operational reliability.

These features make our industrial stainless steel reaction vessels suitable for applications with strict hygiene and purity requirements.

- Excellent Corrosion Resistance

- High Temperature & Pressure Resistance

- Multiple Heating & Cooling Options

- Custom Agitation Systems

- Hygienic & Easy to Clean Design

What Are Stainless Steel Reactor Vessels?

Stainless steel reactor vessels are specialized chemical processing equipment designed for controlled chemical reactions, mixing, and material processing. These industrial reactors feature corrosion-resistant stainless steel construction, advanced mixing systems, and precise temperature control capabilities.

Our stainless steel mixing tanks combine superior materials with innovative engineering to deliver reliable performance in high-temperature, high-pressure, and corrosive environments commonly found in petrochemical and pharmaceutical manufacturing.

Versatile Applications Across Industries

Petrochemical & Refining

Crude oil desulfurization, hydrocracking, catalyst preparation, and aromatic compound production.

Pharmaceutical & Bio-Tech

API synthesis, vaccine production, and sterile mixing tanks complying with GMP standards.

Polymer & Chemical Synthesis

Production of resins, adhesives, polyethylene, and polypropylene.

Environmental & Water Treatment

Wastewater neutralization, chemical precipitation, and air pollution control scrubbers.

Precision-Engineered for Critical Chemical Processes

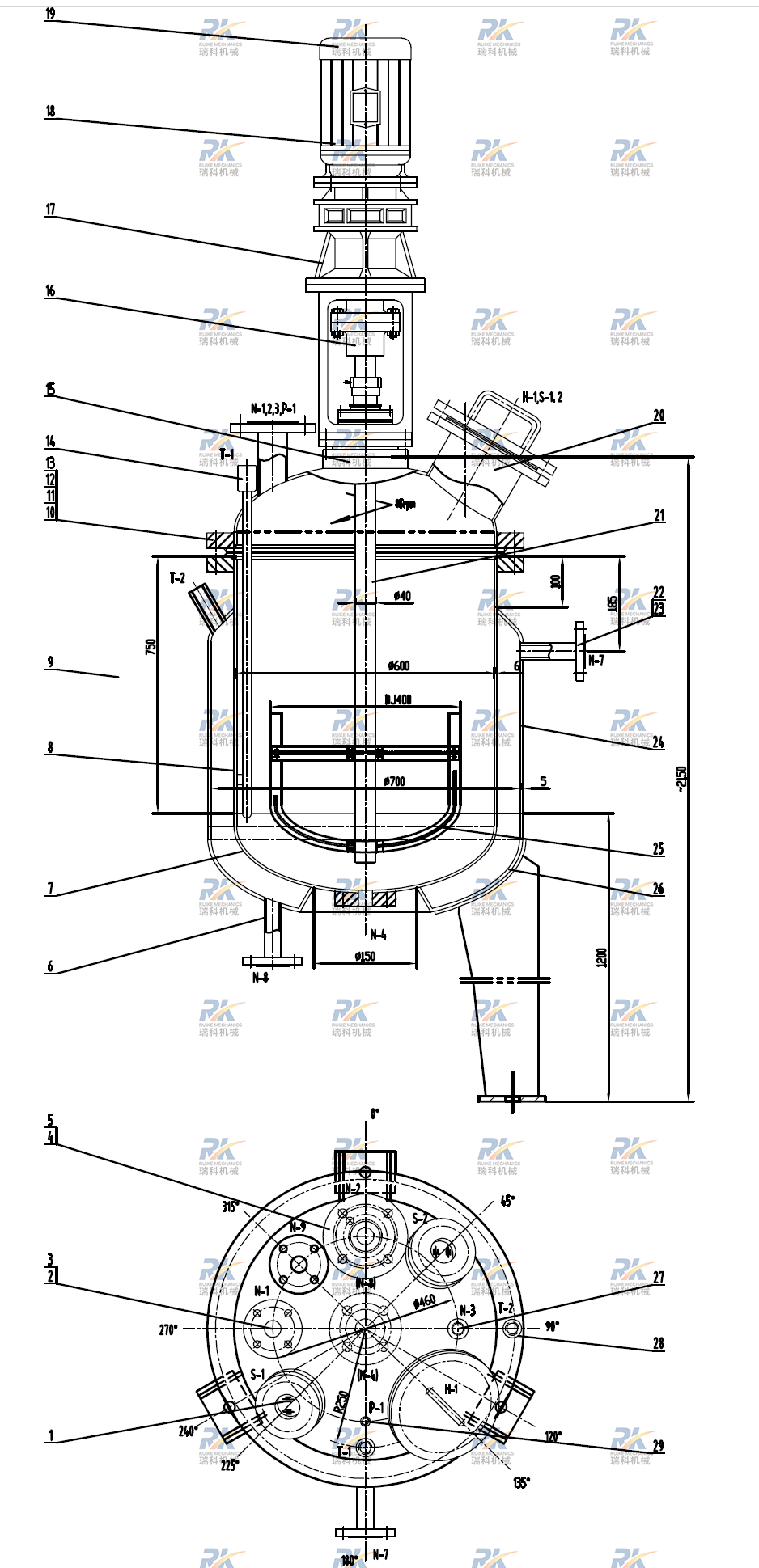

Our Stainless Steel Reactors are more than just storage tanks; they are the heart of your production line. Constructed from premium grades of stainless steel (SS304, SS316L, SS321), Ruike reactors are designed to withstand the rigorous demands of modern chemical processing.

- Robust Material Construction: Superior resistance to acids, alkalis, chlorides, and organic solvents.

- Advanced Thermal Control: Integrated jacketed or coil heating/cooling systems for precise temperature regulation.

- Optimized Agitation: Custom-designed mixing systems (Paddle, Anchor, Turbine, Ribbon) to ensure homogeneity and reaction efficiency.

Why Leading Engineers Choose Ruike Reactors

Superior Corrosion Resistance

Designed for longevity. Our reactors maintain structural integrity even when handling aggressive media like crude oil derivatives and sulfur compounds, significantly reducing maintenance downtime.

High-Performance under Pressure

Engineered to operate safely under extreme conditions. Ideal for high-temperature cracking, polymerization, and hydrogenation processes.

100% Customizable Agitation Systems

Every process is unique. We configure the agitator type, speed, and seal mechanism (mechanical/magnetic) to match your fluid viscosity and mixing requirements.

Hygienic & GMP Compliant

For pharmaceutical and food applications, we offer mirror-polished interiors (Ra ≤ 0.4μm) with zero dead corners, ensuring easy cleaning (CIP/SIP) and preventing cross-contamination.

Technical Specifications & Capacities

We offer a flexible range of configurations. Below are our standard specifications, with custom dimensions available upon request.

Electric Heating Stainless Steel Reactors Specification

| Reactor Capacity | Electric Power | Inner Diameter | Jacket Diameter | Motor Power | Mixing Speed | Applications |

|---|---|---|---|---|---|---|

| 50L Reactor | 8 KW | φ400mm | φ600mm | 0.8 kW | 60-100 rpm | Laboratory scale |

| 100L Reactor | 12 KW | φ500mm | φ700mm | 1.1 kW | 60-100 rpm | Pilot plant |

| 300L Reactor | 24 KW | φ800mm | φ1000mm | 2.2 kW | 60-100 rpm | Small production |

| 500L Reactor | 36 KW | φ900mm | φ1100mm | 3 kW | 60-100 rpm | Medium batch |

| 1000L Reactor | 48 KW | φ1200mm | φ1400mm | 4 kW | 60-100 rpm | Industrial scale |

| 2000L Reactor | 75 KW | φ1400mm | φ1600mm | 4 kW | 60-100 rpm | Large production |

| 3000L Reactor | 90 KW | φ1600mm | φ1800mm | 5.5 kW | 60-100 rpm | High volume |

Steam Heating Stainless Steel Reactor Specifications

| Vessel Size | Inner Diameter | Jacket Diameter | Motor Power | Stirring Speed | Typical Use |

|---|---|---|---|---|---|

| 30L Steam Reactor | φ400mm | φ500mm | 0.6 kW | 60-100 rpm | R&D applications |

| 100L Steam Reactor | φ550mm | φ650mm | 1.1 kW | 60-100 rpm | Process development |

| 500L Steam Reactor | φ900mm | φ1000mm | 3 kW | 60-100 rpm | Pilot production |

| 1000L Steam Reactor | φ1200mm | φ1300mm | 4 kW | 60-100 rpm | Commercial batch |

| 2000L Steam Reactor | φ1400mm | φ1500mm | 5.5 kW | 60-100 rpm | Large scale mixing |

| 5000L Steam Reactor | φ1600mm | φ1700mm | 7.5 kW | 60-100 rpm | Industrial production |

| 32000L Steam Reactor | φ3000mm | φ3200mm | 37 kW | 35-59 rpm | Large volume processing |

Stainless Steel Reactor Installation & Commissioning

Quality Assurance & Global Support

At Ruike Petrochemical, quality is non-negotiable. Our manufacturing process adheres to strict standards including GB150 (Pressure Vessels) and NB/T47013 (Welding Testing).

Our Service Commitment:

Consultation: Free project feasibility analysis and material selection advice.

Installation: Professional guidance on foundation, piping, and electrical setup.

Commissioning: On-site or remote support for testing, calibration, and operator training.

FAQ

Everything you need to know about our manufacturing capabilities, customization options, and shipping.

Q1: Can Ruike customize the reactor design to meet our specific chemical process?

Yes, absolute customization is our core strength. While we offer standard models, most of our Stainless Steel Reactors are tailored to client specifications. We can customize:

Materials: SS304, SS316L, SS321, or Duplex Steel based on corrosion resistance needs.

Agitators: Paddle, Anchor, Frame, Turbine, or Ribbon impellers for different viscosities.

Accessories: Custom nozzle positions, sight glasses, manholes, and explosion-proof motors. Simply share your URS (User Requirement Specification) or drawing, and our engineers will provide a optimized design.

Q2: What pressure and temperature ranges can your reactors handle? Our industrial vessels are designed to withstand rigorous environments.

- Pressure: We manufacture standard atmospheric vessels as well as High-Pressure Reactors capable of handling up to 10 MPa (or customized higher).

Temperature: Our designs accommodate ranges from -40°C (cryogenic) up to 350°C using specialized heating jackets or internal coils.

Q3: How do you ensure the quality and safety of the welding?

Quality is paramount at Ruike Petrochemical. We employ certified welders and strictly adhere to NB/T 47003.1-2009 and GB150 standards. All pressure vessels undergo rigorous testing, including:

Hydrostatic Pressure Testing

X-Ray / Dye Penetrant Inspection (NDT) for weld integrity

Surface Finish Inspection (Polishing Ra checks) We provide full quality documentation and inspection reports with every shipment.

Q4: What is the typical lead time for a customized reactor?

Lead times vary by complexity and volume.

Standard Models: Typically shipped within 15–20 working days.

Custom Fabricated Vessels: Usually require 30–45 days to allow for engineering approval, material procurement, fabrication, and testing. We will provide a detailed production schedule upon order confirmation to help you plan your project timeline.

Q5: Do you offer support for installation and commissioning?

Yes. We provide comprehensive support to ensure your Chemical Reaction Vessel runs smoothly.

Remote Support: Free lifetime technical consultation via video call/email.

Documentation: Detailed installation manuals, electrical diagrams, and foundation drawings are included.

On-site Service: For large-scale projects, we can dispatch engineers to your facility for installation guidance and staff training (subject to contract terms).

Q6: How is the equipment packaged for international shipping?

We have extensive experience in global logistics. All reactors are packed in seaworthy, fumigation-free wooden crates or secured on iron skids to prevent movement. Sensitive components (motors, control panels) are wrapped in protective film and cushioned materials to ensure they arrive in perfect condition, whether shipped LCL or FCL.

Q7: What is the Minimum Order Quantity (MOQ)?

For industrial equipment like Mixing Tanks and Reactors, our MOQ is 1 Unit. We value partners of all sizes, from pilot-plant startups to large-scale petrochemical refineries.

Recommended Complementary Equipment

From single components to complete turn-key refineries, Ruike provides integrated engineering support to ensure all equipment works at peak performance.

Pyrolysis Machine

Converts waste tires, plastics, and rubber into fuel oil, carbon black, and steel wire through high-temperature thermal decomposition in an oxygen-free environment.

Oil Distillation Plant

Further refines tire oil, plastic oil, or used motor oil into high-quality diesel or gasoline fractions through fractional distillation and catalyst processing.

Shell and Tube Heat Exchangers

Beyond condensation, these units are used for liquid-to-liquid heating or cooling and as reboilers in distillation processes.