High-Efficiency Shell and Tube Condensers for Petrochemical & Industrial Applications

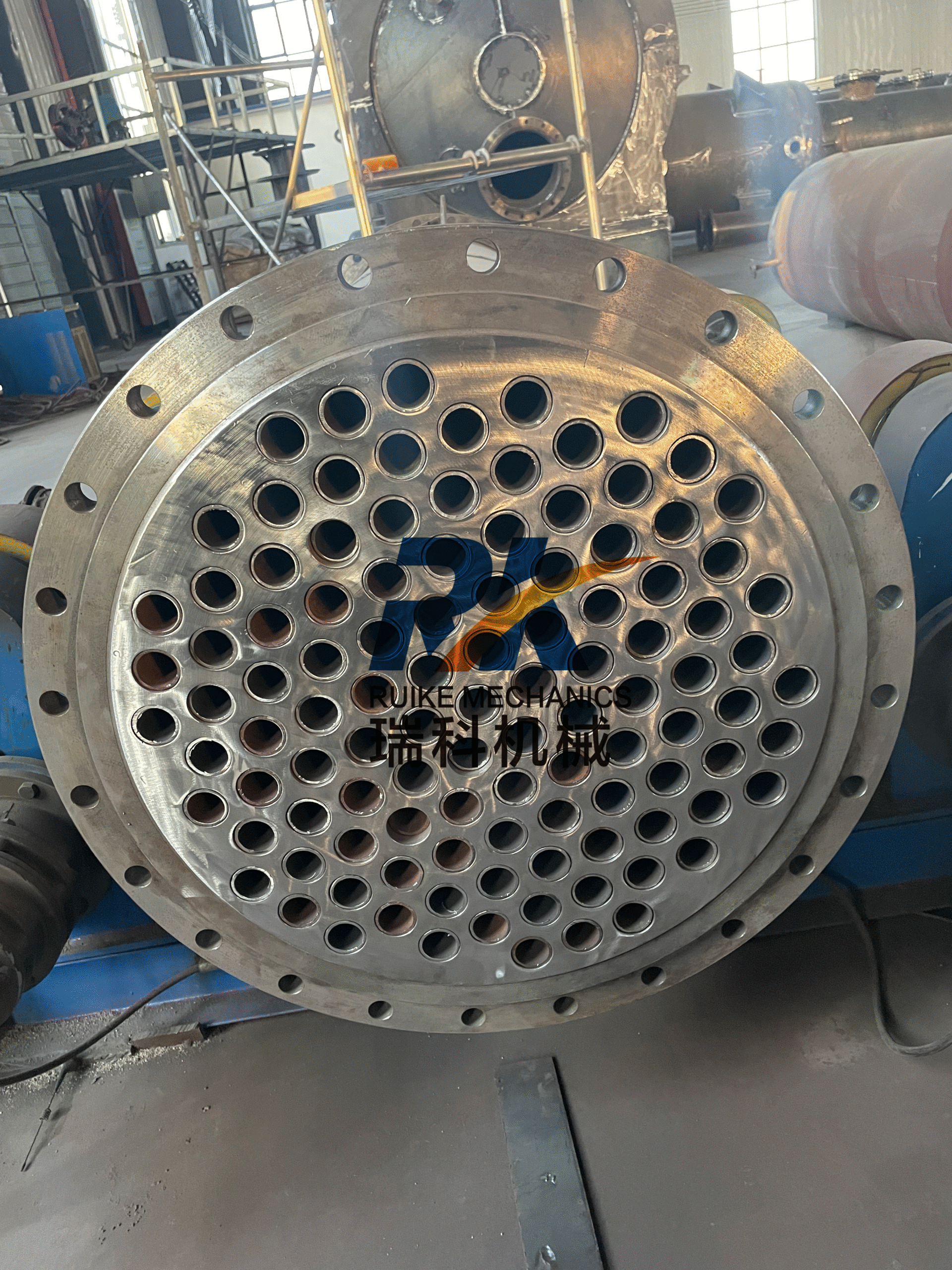

Ruike Industrial Shell and Tube Condenser

At Ruike Petrochemical, we understand that thermal efficiency is the heartbeat of your processing plant. Our Shell and Tube Condensers are engineered to deliver superior heat transfer performance under the most demanding conditions. Whether you are optimizing a crude oil distillation unit, managing waste oil recycling, or upgrading chemical processing lines, Ruike provides robust, ASME-compliant heat exchange solutions tailored to your specific operational parameters.

With over 19 years of manufacturing expertise and a footprint in 78+ countries, we don’t just sell equipment; we deliver reliability, longevity, and process optimization.

Ruike Shell and Tube Condenser Feature

shell & tube heat exchanger

- Proven performance in heavy industry: widely used across petrochemical, refinery, power, pharmaceutical and aviation applications.

- Flexible configurations: single-, double- and multi-pass tube arrangements let you tune heat transfer and pressure drop for each process stream

- Material options for corrosive services: carbon steel, stainless steel, or mixed constructions to balance cost and corrosion resistance.

Why Choose Ruike Shell and Tube Heat Exchangers?

Designed for critical service, our exchangers balance high thermal efficiency with low maintenance requirements.

Optimized Thermal Design:

Advanced tube bundle configurations (Single-pass, Multi-pass, U-tube) maximize the heat transfer surface area, ensuring rapid condensation of vapors and precise temperature control.

Corrosion Resistance & Durability:

Material selection is critical. We offer Carbon Steel, Stainless Steel (304/316L), and Special Alloys to withstand corrosive media like sulfur-rich crude oil, acidic gases, and cooling water with high chloride content.

ASME & CE Compliance:

Safety is non-negotiable. Our pressure vessels are manufactured in strict accordance with ASME and CE standards, ensuring safe operation under high pressure and temperature cycling.

Ease of Maintenance:

Features like removable tube bundles and accessible headers allow for straightforward cleaning and inspection, minimizing downtime during plant turnarounds.

Advantages of Ruike Shell and Tube Condensers

Superior Heat Transfer Efficiency

The multi-tube design significantly increases heat transfer surface area, enabling rapid thermal energy transfer from process fluids to cooling media. This enhanced efficiency translates to:

- Reduced energy consumption

- Faster processing times

- Improved overall system performance

Robust Construction and Durability

Premium materials and precision manufacturing ensure:

- High-pressure and temperature capabilities

- Resistance to thermal cycling

- Extended operational lifespan

- Minimal maintenance requirements

Versatile Application Adaptability

Customizable design parameters allow for:

- Tube count optimization

- Material selection based on process media

- Flow arrangement modifications

- Capacity scaling for various throughput requirements

Technical Specifications & Configuration

We offer standard models and fully customized designs to match your P&ID requirements.

Feature | Specification Range |

Heat Transfer Area | 0.5 m² – 500 m² (Customizable for large-scale plants) |

Shell Material | Q345R (Boiler Steel), Stainless Steel 304/316L |

Tube Material | Carbon Steel, Stainless Steel, Copper, Titanium Alloy |

Design Pressure | Up to 10.0 MPa (High-pressure designs available) |

Design Temperature | -20°C to 500°C |

Configuration Types | Fixed Tube Sheet: Cost-effective for low fouling fluids. Floating Head: Ideal for high thermal expansion differentials. U-Tube: Best for high-pressure/temperature applications. |

Connections | ANSI / ASME / DIN Flanges |

Request A Quote

Structural Design and Components

Core Components of Shell and Tube Condensers

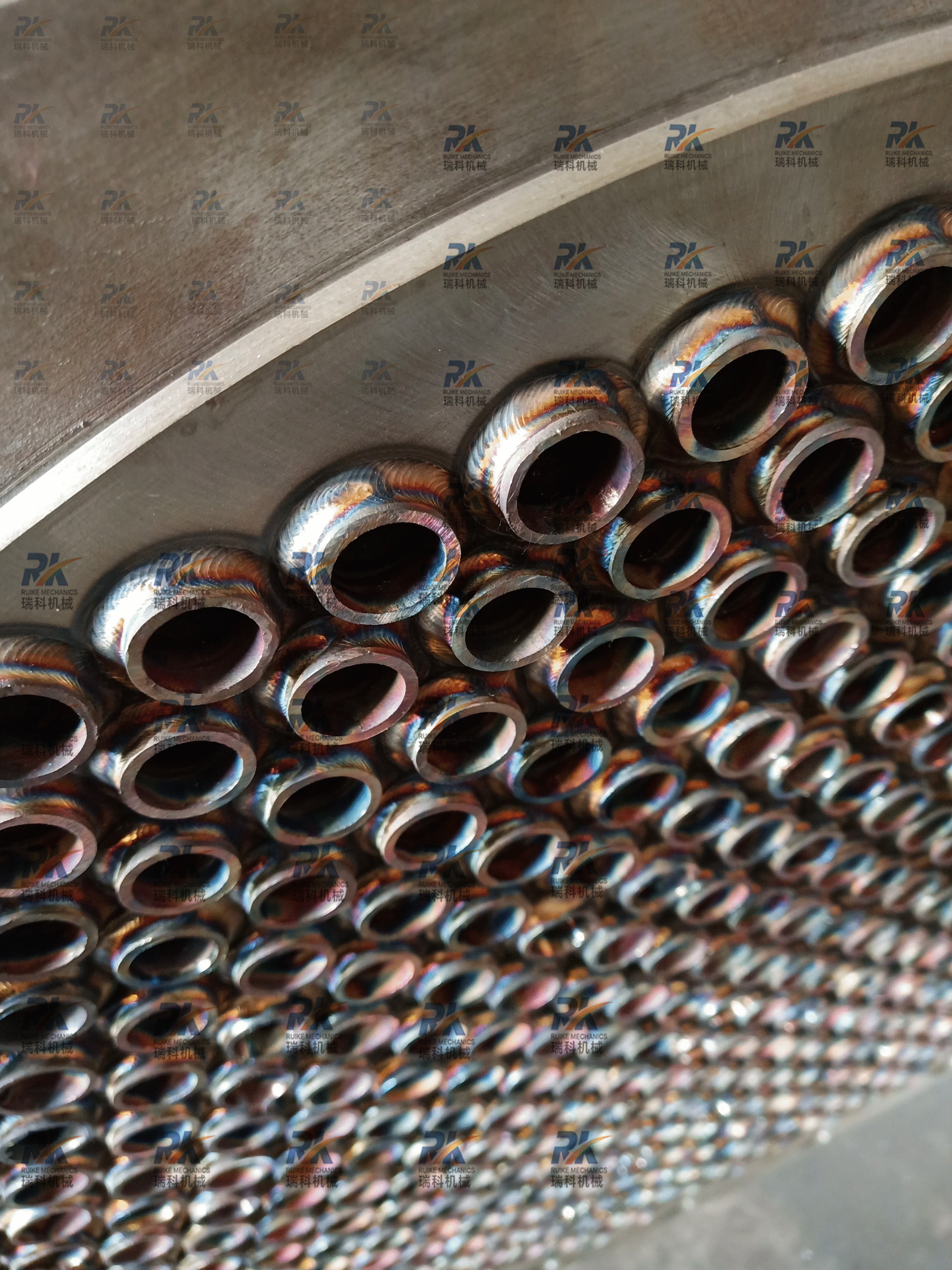

1. Condenser Tubes The heart of any shell and tube heat exchanger system, condenser tubes are precision-manufactured from high-conductivity materials including:

- Copper tubes for superior heat transfer

- Aluminum construction for lightweight applications

- Stainless steel grades (316, 316L) for corrosive environments

- Enhanced surface tubes for improved heat transfer coefficients

2. Cooling Medium Distribution System Engineered piping networks ensure optimal cooling fluid distribution throughout the shell and tube condenser, featuring:

- Precision-designed inlet headers for uniform flow distribution

- Temperature and flow control capabilities

- Compatible with various cooling media (water, glycol, refrigerants)

3. Inlet/Outlet Piping Configuration Process connections designed for:

- High-temperature vapor inlet systems

- Condensate discharge optimization

- Leak-proof sealing technologies

- Easy maintenance access

4. Flow Distribution Manifolds Advanced shell and tube heat exchanger designs incorporate:

- Distribution Headers: Ensure uniform cooling medium allocation

- Collection Manifolds: Efficient condensate gathering and removal systems

Shell and Tube Heat Exchanger Design Types

Fixed Tube Sheet Heat Exchangers

Advantages:

- Simple, compact construction

- High pressure capability

- Easy tube-side cleaning

- Simple tube replacement procedures

Applications: Ideal for clean shell-side media with minimal fouling potential and moderate temperature differentials.

U-Tube Heat Exchangers

Design Benefits:

- Single tube sheet construction

- Unlimited thermal expansion capability

- High pressure and temperature ratings

- Cost-effective manufacturing

Optimal Use: High-temperature, high-pressure applications with clean tube-side fluids.

Floating Head Shell and Tube Condensers

Key Features:

- Thermal expansion accommodation

- Complete tube bundle removal capability

- Both shell-side and tube-side cleaning access

- Elimination of thermal stress

Applications: Perfect for high temperature differential applications and shell-side media prone to fouling.

Critical Applications in the Petrochemical Industry

Critical Role in Oil Refining Processes

Our shell and tube condensers are the industry standard for robust heat transfer in:

acting as overhead vapor condensers for Crude Oil Distillation Units (CDU) and Vacuum Distillation Units (VDU). They efficiently convert hydrocarbon vapors back into liquid fractions (diesel, gasoline, kerosene).

Crucial for the condensation stage in pyrolysis and waste oil distillation plants, ensuring high oil recovery rates and preventing vapor loss.

Controlling reaction temperatures and solvent recovery in reactors and evaporators.

Steam surface condensers and auxiliary cooling for turbine exhaust.

Customized Project

Explore your project plan

We offer you the equipment lists, cost analysis statements, and layout according to your site of regular models.

If you have any special requirements about your project, please contact Nancy, and we will offer you a customized project plan for you.

Ruike Engineering Advantage: From Design to Delivery

With extensive experience in petrochemical equipment manufacturing, Ruike delivers shell and tube heat exchanger solutions that meet the most demanding industrial requirements. Our comprehensive understanding of process conditions, material compatibility, and performance optimization ensures superior results for every application.

We serve EPC contractors, OEM partners, and end-users with a complete service lifecycle:

Consultative Design:

We review your process data (fluid properties, temperatures, flow rates) to recommend the most efficient exchanger type.

Precision Manufacturing:

Utilizing automated submerged arc welding and 100% X-Ray NDT testing to guarantee leak-proof seams.

Global Logistics:

Experience in handling heavy, oversized cargo shipping to destinations globally (USA, UK, Southeast Asia, Middle East).

Q1: What design standards do Ruike shell and tube condensers adhere to?

We strictly follow international engineering standards to ensure safety and compatibility. Our condensers are designed and manufactured in accordance with ASME Section VIII Div 1 and TEMA (Tubular Exchanger Manufacturers Association) classifications (Class R, C, or B). We can also comply with API 660 standards for refinery services upon request.

Q2: Can you customize the heat exchanger design based on my specific fluid properties?

Yes. We do not just sell off-the-shelf products. Our engineering team performs thermal calculations based on your specific operating parameters—including flow rates, inlet/outlet temperatures, operating pressure, and fluid viscosity. We optimize the tube layout, baffle spacing, and pass arrangements to achieve maximum heat transfer efficiency for your unique process.

Q3: How do you handle corrosive media in the refining process?

Material selection is critical for longevity. While Carbon Steel (Q345R) is standard for non-corrosive applications, we recommend and supply Stainless Steel (304/316L), Duplex Stainless Steel, or Titanium Alloy tubes for processing corrosive crude oil, acidic water, or high-chloride cooling water. We will advise on the most cost-effective material to prevent premature failure.

Q4: How do you ensure the quality and safety of the pressure vessels before shipment?

Quality control is rigorous at Ruike. Every unit undergoes a series of Non-Destructive Tests (NDT), including Radiographic Testing (RT/X-Ray) on weld seams to detect internal defects and Hydrostatic Pressure Testing to ensure leak-proof integrity. Mill Test Certificates (MTC) and inspection reports are provided with the equipment.

Q5: Are your condensers designed for easy maintenance and cleaning?

Yes. We understand that fouling is a common challenge in petrochemical industries. We offer removable tube bundle designs (such as U-tube or Floating Head types) which allow the bundle to be pulled out for mechanical cleaning or high-pressure water jetting. This design significantly reduces maintenance downtime during plant turnarounds.

Q6: What is the typical lead time for a custom shell and tube condenser?

Lead times vary based on size and material availability. Generally, a standard unit takes 25 to 45 days from drawing approval to completion. For urgent project timelines or complex alloy fabrications, please contact our sales team for a precise schedule.

Q7: Do you provide shipping solutions for oversized heat exchangers?

Absolutely. We have extensive experience exporting heavy equipment to over 78 countries. We use reinforced steel frame packaging or wooden crates compliant with ISPM 15 standards to prevent damage during sea freight. We can handle logistics terms including FOB, CIF, or DAP to your project site.

Recommended Complementary Equipment

From single components to complete turn-key refineries, Ruike provides integrated engineering support to ensure all equipment works at peak performance.

Pyrolysis Machine

Converts waste tires, plastics, and rubber into fuel oil, carbon black, and steel wire through high-temperature thermal decomposition in an oxygen-free environment.

Oil Distillation Plant

Further refines tire oil, plastic oil, or used motor oil into high-quality diesel or gasoline fractions through fractional distillation and catalyst processing.

Pressure Vessels & Storage Tanks

Specialized containers designed to hold liquids or gases at pressures substantially different from the ambient pressure, fully compliant with ASME Boiler and Pressure Vessel Code.