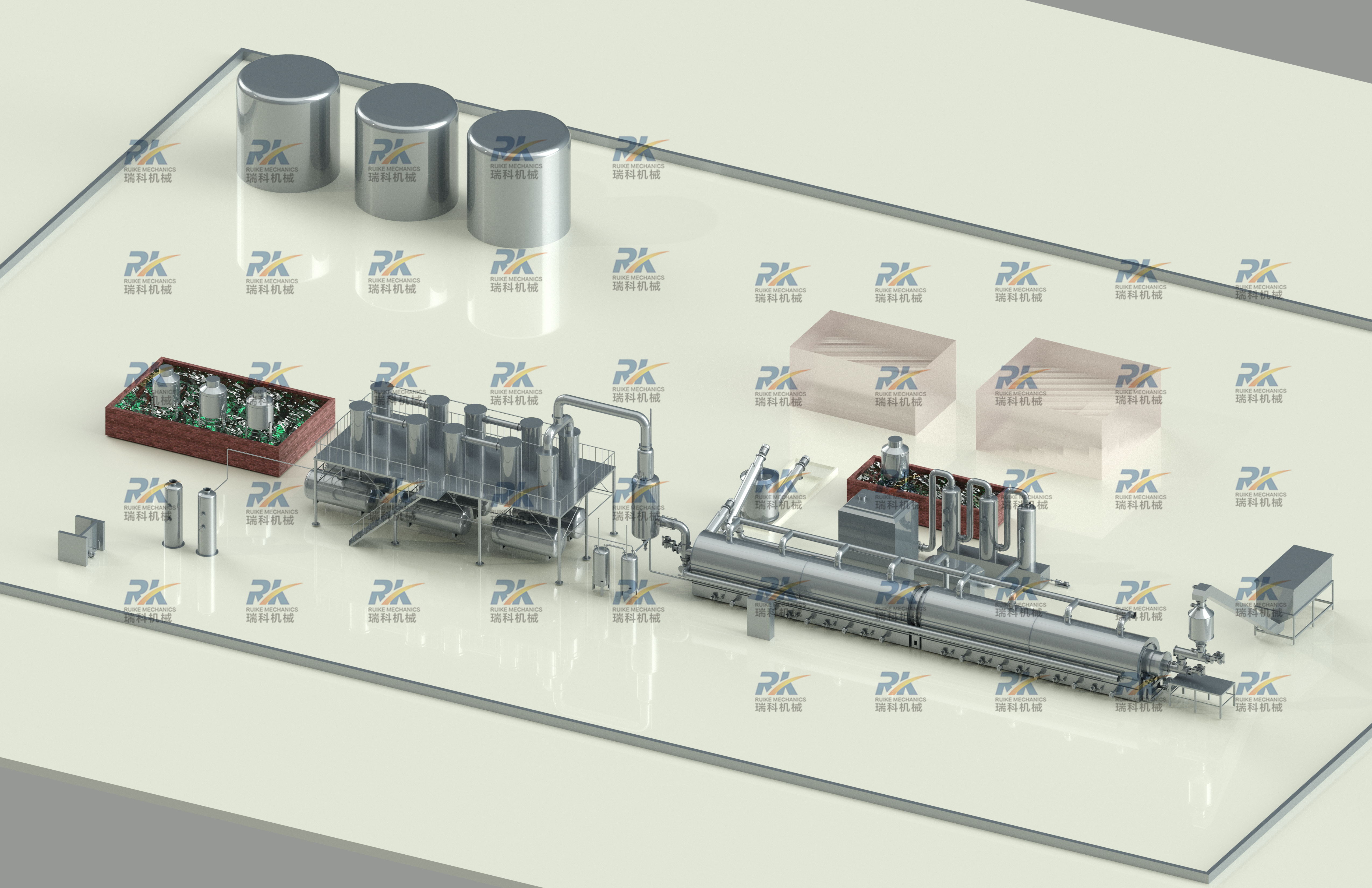

Fully Continuous Pyrolysis Plant: Industrial Scale Efficiency

Designed for large-scale recycling projects. Experience 24/7 non-stop operation, fully automated control, and maximum profitability with minimal labor requirements.

The Ultimate Solution for High-Volume Recycling

When your project demands scale, stability, and low operational costs.

Ruike Continuous Pyrolysis Machine Key Specs

- 24/7 Non-Stop Running:

Unlike Batch plants that need to cool down every day, our Continuous Plant feeds raw material and discharges carbon black simultaneously at high temperatures. No downtime means higher daily output.

- Massive Capacity:

A single line can process 30 to 50 tons of waste per day. Perfect for government projects or large industrial parks.

- Minimal Labor Cost:

Thanks to the PLC/DCS Control System, the entire line requires only 1-2 operators to monitor the screens. This is a huge cost-saver in regions with high labor wages (e.g., Europe, USA).

- Higher Oil Yield & Quality:

Continuous reaction temperature prevents fluctuation, ensuring the oil yield is 3-5% higher than batch plants and the quality is more stable.

Fully Automated Process: Safety & Efficiency

Working Process :

1. Pre-treatment (Mandatory):

Waste tires must be shredded into rubber powder (5-15mm) or plastics crushed into flakes.

2. Continuous Feeding:

The sealed screw conveyor pushes material into the reactor continuously.

4. Continuous Discharging:

Carbon black is discharged automatically from the bottom while the machine is running, passing through a cooling jacket.

5. Gas Cleaning & Condensing:

Oil gas goes through the condensing system; Tail gas is recycled for heating; Smoke is purified.

6. PLC Monitoring:

All steps are monitored and controlled via the central control room.

Available Models & Specifications

Model | Daily Capacity | Reactor Size (D*L) | Operation Mode | Control System | Floor Area (LWH) |

RKLXLJ-30 | 30 Tons | 2.0m * 14m | Fully Continuous | PLC / DCS | 45m * 15m * 10m |

RKLXLJ-50 | 50 Tons | 2.4m * 18m | Fully Continuous | PLC / DCS | 55m * 20m * 10m |

Note: We can customize larger capacities (e.g., 100TPD) by parallel connection of multiple lines.

Ask for Technical Proposal of 30TPD & 50TPD

Know More Project Cases by Ruike Petrochemical

Technological Breakthroughs by Ruike

Continuous technology is difficult. Here is how we solved the challenges.

- Unique Sealing Technology (The Key):

We use a proprietary Multi-Stage Dynamic Sealing System combined with graphite packing. It ensures zero gas leakage even during 24/7 rotation and thermal expansion.

- Anti-Coking Design:

We use a special Internal Scraper System inside the reactor to prevent plastic/rubber from sticking to the wall (coking), ensuring long-term stable operation without blockage.

- Internal Screw Conveyor:

Customized internal welding plates move the material forward automatically, ensuring even heating and complete pyrolysis.

- PLC/DCS Integration:

Partnering with Siemens/Schneider, we provide top-tier electronic control systems for real-time monitoring of pressure, temperature, and flow rates.

Environmental & Energy Efficiency

Sustainable & Eco-Friendly

Closed-Loop Operation:

The entire system from feeding to discharging is fully enclosed. No dust, no smell, no leakage.

Self-Sufficient Energy:

The Syn-gas (Tail gas) generated is enough to heat the system. Once the process stabilizes, you need zero external fuel, maximizing your profit margin.

European Standard Emission:

Equipped with our advanced Desulfurization and Dedusting tower, emissions meet the strictest global environmental standards.

Proven in the Field: Real Site Footage

See our continuous plants running in client factories.

Your Journey with Ruike: Simple, Transparent, Secure

Your Project Roadmap

-

1. Feasibility Study: We analyze your raw material supply and land area.

-

2. Engineering Design: We provide P&ID, Site Layout, and Civil Foundation drawings.

-

3. Contract & Production: Manufacturing takes 40-60 days for Continuous lines.

-

4. Weekly Reporting: Track your machine's progress via photos/videos.

-

5. Pre-shipment Inspection: Trial running (cold test) at our factory.

-

6. Shipping: Logistics arrangement to your destination port.

-

7. On-site EPC: We send a team of engineers for assembly, commissioning (60-90 days), and training.

Global Logistics for Heavy Equipment

Modular Design:

Our continuous pyrolysis machine series is designed in modules. The long reactor is shipped in sections (or via Bulk Vessel), while other parts fit into 40HQ containers.

Installation Planning:

We provide a detailed Container Loading Plan and Foundation Drawing before shipping, so you can prepare civil work in advance.

Secure Lashing:

Heavy components are reinforced with steel cables on Flat Racks to ensure they arrive in perfect condition.

Frequently Asked Questions about Continuous Pyrolysis Machines

Q1: Coking (blockage) is the biggest failure in continuous plants. How do you prevent it?

Ruike uses a proprietary Internal Scraper & Cleaning System. Specially designed scrapers rotate to constantly peel off any sticky rubber/plastic from the inner wall. Combined with precise temperature control, we guarantee zero coking.

Q2: How do you seal the reactor while it rotates 24/7?

We utilize a Multi-Stage Dynamic Sealing Technology with flexible graphite rings and a nitrogen (N2) buffer system. This structure accommodates thermal expansion and ensures 100% gas-tightness.

Q3: Can it run for a whole year without stopping?

No machine runs forever. Based on operational data, we recommend a “25+2” cycle: Run continuously for 25-28 days, then stop for 2-3 days for routine inspection. This ensures the plant lasts for 8-10 years.

Q4: What happens if there is a power cut?

The system has Fail-Safe Logic. The PLC shuts down fuel valves, and the optional Emergency Diesel Generator keeps the reactor rotating to prevent deformation.

Q5: Can I feed whole tires?

No. You must shred tires into rubber powder (5-15mm). This is mandatory for the sealed screw feeder.

Q6: How many workers are required?

Only 2 workers per shift (Control room + Patrol), thanks to PLC automation.

Q7: Coking (blockage) is the biggest failure in continuous plants. How do you prevent it?

Excellent question. Ruike uses a proprietary Internal Scraper & Cleaning System. Inside the reactor, specially designed scrapers rotate to constantly peel off any sticky rubber/plastic from the inner wall. Combined with our precise temperature control (avoiding overheating spots), we guarantee zero coking for long-term operation.

Q8: How do you seal the reactor while it rotates 24/7?

We don’t use simple packing. We utilize a Multi-Stage Dynamic Sealing Technology combining flexible graphite rings and a nitrogen (N2) buffer system. This structure accommodates the thermal expansion of the reactor and ensures 100% gas-tightness even after months of continuous running.

Q9: What is the realistic maintenance cycle? Can it run for a whole year?

No machine runs forever without maintenance. Based on our operational data, we recommend a “25+2” cycle: Run continuously for 25-28 days, then stop for 2-3 days for routine inspection (cleaning pipes, checking pumps). This scheduled maintenance ensures the plant lasts for 8-10 years, rather than breaking down unexpectedly.

Q10: Does the continuous plant have a higher oil yield than the batch plant?

Yes, typically 3%-5% higher.

Reason: In a continuous process, the temperature is kept constant and stable. This prevents the “temperature fluctuation” found in batch processing (heating up and cooling down), which often cracks oil gas into non-condensable gas. Stable temperature means more gas condenses into liquid oil.

Q11: What happens if there is an emergency (e.g., power cut)?

The system is designed with Fail-Safe Logic.

1. The PLC will automatically shut down fuel valves.

2. The Emergency Diesel Generator (optional) will kick in to keep the reactor rotating (to prevent deformation from uneven heat).

3. Safety valves will release pressure if needed. Your asset is protected even during blackouts.

Recommended Complementary Equipment

From single components to complete turn-key refineries, Ruike provides integrated engineering support to ensure all equipment works at peak performance.

Pyrolysis Machine

Converts waste tires, plastics, and rubber into fuel oil, carbon black, and steel wire through high-temperature thermal decomposition in an oxygen-free environment.

Oil Distillation Plant

Further refines tire oil, plastic oil, or used motor oil into high-quality diesel or gasoline fractions through fractional distillation and catalyst processing.

Pressure Vessels & Storage Tanks

Specialized containers designed to hold liquids or gases at pressures substantially different from the ambient pressure, fully compliant with ASME Boiler and Pressure Vessel Code.

Shell and Tube Heat Exchangers

Beyond condensation, these units are used for liquid-to-liquid heating or cooling and as reboilers in distillation processes.