Modular Crude Oil Distillation Units (CDU & VDU)

Turn Raw Crude Oil into High-Value Diesel, Kerosene, and Naphtha directly at the source.

Why Refine Pyrolysis Oil?

Maximize Your Margins

Deploy scalable refining capacity with Ruike’s Skid-Mounted Mini Refineries. Engineered for oil fields and independent investors, our Atmospheric & Vacuum Distillation Units (AVDU) process Light and Heavy Crude Oil into commercial-grade fuels with ASTM compliance.

Higher Selling Price:

Refined diesel sells for 2x - 3x the price of raw tire oil. It can be used in tractors, trucks, ships, and generators directly.

Longer Storage Life:

Raw tire oil oxidizes and turns black in weeks. Our refined diesel, treated with Anti-Oxidation additives, stays golden and stable for months.

Wider Application:

Solves the "bad smell" complaint from customers. Clean diesel is easier to sell to more industries.

Professional Refinery Process: Atmospheric & Vacuum Rectification

Moving beyond simple boiling. We bring petrochemical refinery standards to waste recycling.

- 1. Dehydration & Pre-treatment: Remove water and light impurities to prevent bumping.

- 2. Molten Salt Heating: Unlike thermal oil (max 300°C), our Molten Salt System heats up to 450°C. This ensures heavy crude components are fully distilled, increasing yield by 5%.

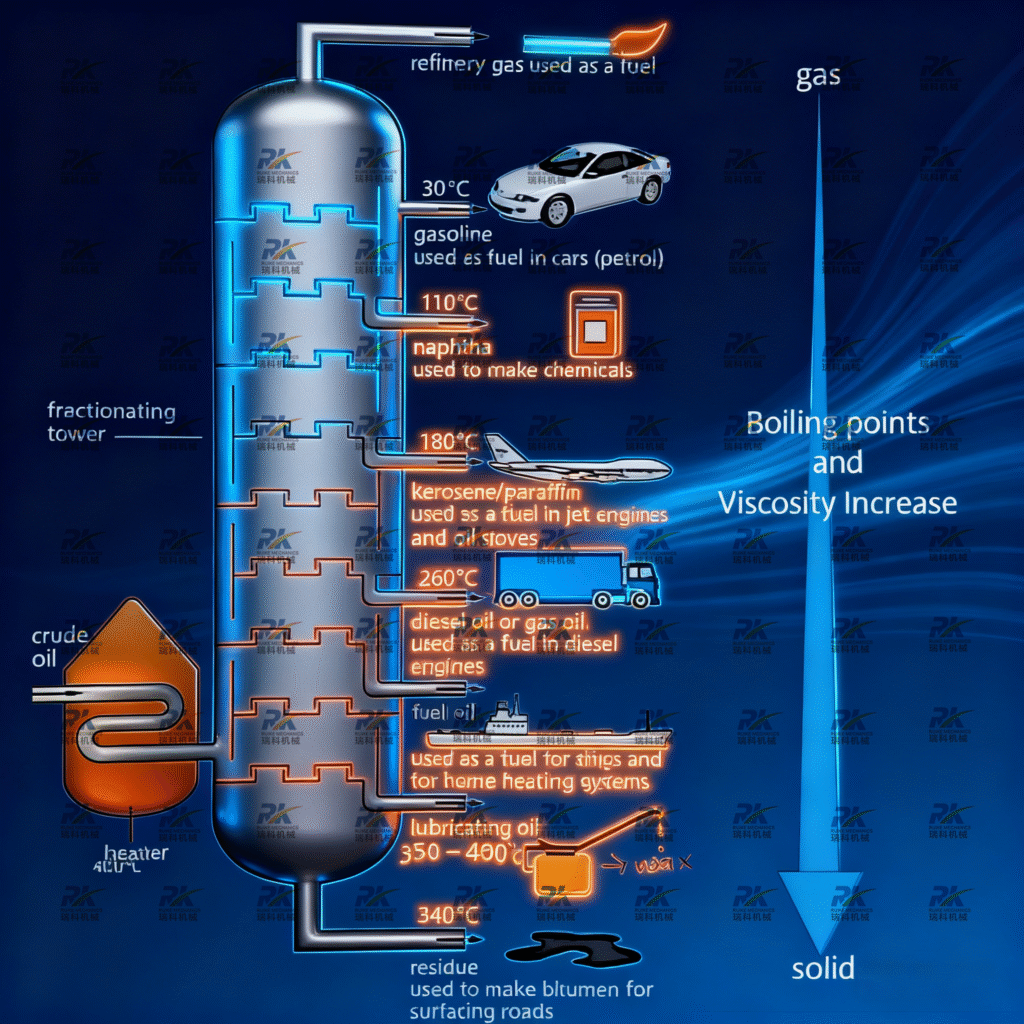

- 3. Atmospheric Distillation (ADU): The primary stage where lighter fractions like Naphtha and Kerosene are flashed off. Our Structured Packing Columns ensure high separation efficiency, preventing the mixing of cuts (e.g., keeping diesel flash points safe).

- 4. Vacuum Distillation (VDU): Essential for processing Heavy Crude Oil. By reducing pressure to -0.098 MPa, we lower the boiling point of heavy fractions. This allows you to recover more diesel from the heavy residue without thermal cracking (coking), significantly boosting your Liquid Yield.

- 5. Rectification (Precise Separation): Inside the Packed Column Tower, rising vapor and falling liquid contact repeatedly. This separates the oil into precise cuts: Gasoline, Kerosene, and Diesel.

- 6. Gas-Phase Catalytic Desulfurization: Our proprietary catalyst tower targets the sulfur-carbon bonds. While no non-hydrogenation technology can remove 100% of sulfur, our system efficiently cracks Mercaptans and Sulfides, significantly reducing corrosion and smell without using hazardous acids.

Multi-Product Fractionation

One machine, multiple outputs.

Transporting raw crude oil eats into your margins. Ruike provides Turnkey Mini Refineries (10 TPD – 500 TPD) that allow you to refine on-site and sell higher-value finished products to the local market.

- 1. Naphtha / Gasoline (< 180°C): ~10% Yield.

Clear, solvent-grade quality. Can be used as chemical feedstock or gasoline blendstock.

- 2. Light Diesel AGO(180°C - 350°C): ~80-85% Yield.

Color: Light Yellow / Golden (0.5 – 1.0).

Flash Point: > 60°C (Safe for storage).

Sulfur content adjustable via our Catalytic Desulfurization Tower or optional Hydrogenation unit. Meets industrial engine standards.

- 3. Heavy Fuel Oil: (> 350°C): ~5-10% Yield.

Suitable for bitumen production or power plant fuel.

- 4. Combustible Gas:

Recycled to heat the reactor.

Typical Output Diesel Specifications

Achieve industrial standard diesel. (Note: Data based on standard Tire Pyrolysis Oil input.)

Parameter | Unit | Typical Result | Standard Reference |

Flash Point | °C | 60 – 70 | Safe for storage & transport |

Cetane Number | – | 45 – 55 | Good ignition power |

Density (at 15°C) | g/cm³ | 0.82 – 0.85 | Standard Diesel range |

Color | – | 0.5 – 1.0 | Light Yellow / Golden |

Sulfur Content | ppm | 150 – 500 * | Euro III / Euro IV |

Important Note on Sulfur:

The final sulfur content is highly dependent on the raw material’s initial sulfur level and chemical structure. Our catalytic system typically removes 60%-85% of sulfur. For ultra-low sulfur requirements (<10ppm), a Hydrogenation unit may be required.

Engineered for Remote & Industrial Operations

Modular & Skid-Mounted:

Pre-assembled modules fit into standard 40HQ containers. Rapid installation in remote oil fields with minimal civil work.

Feedstock Versatility:

capable of processing Sweet Crude, Sour Crude, and even Sludge Oil (with pre-treatment).

ASME Certified Standards:

Pressure vessels and piping are designed to ASME/CE standards, ensuring safety and insurability.

DCS/PLC Automated Control:

Monitor flow rates, temperatures, and pressure from a central control room—minimal manpower required.

Atmospheric & Vacuum Distillation vs. Pot Distillation

Why Ruike technology is superior to traditional "boiling pots".

Ruike Modular Refinery (CDU/VDU)

-

Separation Method: Fractionation Column (Precise Cuts)

-

Products Multi-Stream: Naphtha, Kerosene, Diesel

-

Heating Source: Molten Salt (Indirect, Safe, 450°C)

-

Yield Efficiency High: Recovers max value from residue

-

Crude Flexibility: Handles Light & Heavy Crude (API 10-50)

Traditional Simple Distillation

-

Separation Method: Simple Pot Boiling (Mixed Oil)

-

Products Single Stream: Mixed dirty fuel

-

Heating Source: Direct Fire / Coal (Hazardous)

-

Yield Efficiency Low: High waste/sludge left

-

Crude Flexibility: Limited to Light Crude only

Engineered for Efficiency

Key Components of Ruike Distillation Machine Recycling Crude Oil into Diesel & Gasoline

- 1. Molten Salt Heating System:

The only heating medium stable at 450°C. Essential for processing heavy crude oil to get maximum diesel yield.

- 2. Rectification Tower:

Stainless steel tower with structured packing. The “brain” that separates gasoline from diesel based on boiling points.

- 3. Catalytic Tower:

Filled with our special Desulfurization Catalyst. Removes mercaptans and sulfides without using chemicals.

- 4. Tubular Condensers:

Shell-and-tube design for maximum cooling efficiency, ensuring 100% oil recovery.

Customized Project

Explore your project plan

We offer you the equipment lists, cost analysis statements, and layout according to your site of regular models.

If you have any special requirements about your project, please contact Nancy, and we will offer you a customized project plan for you.

Frequently Asked Questions

Q1: Can your machine produce Euro V (10ppm) ultra-low sulfur diesel?

It depends heavily on your Raw Material.

The Principle: Our machine uses Gas-Phase Catalytic Desulfurization. It is highly effective at removing Reactive Sulfur (like Mercaptans and Sulfides) by breaking their bonds and converting them into gas (H2S) to be scrubbed.

The Limitation: However, if your waste oil contains high levels of Non-Reactive Sulfur (like Thiophenes, which are chemically stable cyclic structures), simple catalytic distillation cannot remove them all. Removing Thiophenes completely typically requires a high-pressure Hydro-desulfurization (HDS) plant costing millions of dollars.

The Reality: For most standard tire oil, our machine can reduce sulfur to 150ppm – 500ppm (Euro III/IV standard), which is perfect for industrial heating, trucks, tractors, and generators.

Q2: Will the diesel turn black after storage?

No. This is a common problem with “Acid-Washing” machines. Ruike machines use Vacuum Distillation (preventing cracking) and Anti-Oxidant Additives. Our diesel stays golden for 6-12 months.

Q3: Can I process Crude Oil and Tire Oil in the same machine?

Yes. The machine is versatile. However, crude oil often contains more water and light components (gasoline). We will adjust the P&ID design (e.g., adding a larger Pre-treatment system) to handle your specific crude type.

Q4: What is the operating cost?

The main cost is heating fuel and catalyst consumption.

Fuel: Self-sufficient after the process stabilizes (using recycled gas).

Catalyst: Cost is approx. $10 – $15 USD per ton of oil. Much cheaper than acid chemicals.

Q5: Why does the Sulfur content vary even with the same machine?

Because sulfur exists in different chemical forms in different waste oils.

Scenario A: If your input oil has sulfur mostly in “simple chains,” our catalyst can remove 90%+ of it.

Scenario B: If your input oil (e.g., heavy crude) has sulfur locked in “complex rings,” the reduction rate might be lower.

Recommendation: We strongly suggest you send us a sample of your raw oil. We can test it in our lab to give you a precise predicted output report before you buy.

Q6: Can this machine handle high-sulfur (Sour) Crude?

Yes. While physical distillation separates fractions, sulfur reduction requires chemical treatment. Our unit includes a Gas-Phase Catalytic Tower to reduce mercaptans. For strict Euro V (10ppm) standards, we can integrate a modular Hydro-desulfurization (HDS) unit.

Q7: What is the difference between this and your Tire Oil machine?

While the core rectification principle is similar, our Crude Oil units are designed with more fractionation stages to capture the “Middle Distillates” (Kerosene/Diesel) more effectively and handle the specific water/salt content found in raw crude.

Q8:What capacities are available?

We manufacture units from 10 Tons/day (Pilot) up to 500 Tons/day (Commercial).

Recommended Complementary Equipment

From single components to complete turn-key refineries, Ruike provides integrated engineering support to ensure all equipment works at peak performance.

Pyrolysis Machine

Converts waste tires, plastics, and rubber into fuel oil, carbon black, and steel wire through high-temperature thermal decomposition in an oxygen-free environment.

Oil Distillation Plant

Further refines tire oil, plastic oil, or used motor oil into high-quality diesel or gasoline fractions through fractional distillation and catalyst processing.

Pressure Vessels & Storage Tanks

Specialized containers designed to hold liquids or gases at pressures substantially different from the ambient pressure, fully compliant with ASME Boiler and Pressure Vessel Code.

Shell and Tube Heat Exchangers

Beyond condensation, these units are used for liquid-to-liquid heating or cooling and as reboilers in distillation processes.