Advanced Used Engine Oil Re-refining Plant

Convert Dirty Waste Motor Oil into Premium Diesel or Base Oil with Zero Acid & Zero Sludge

Why Recycle Engine Oil?

Waste motor oil is hazardous, but it is also liquid gold.

Stop treating waste oil as garbage. Ruike’s High-Vacuum Distillation Technology recovers up to 85%-90% of usable oil from waste engine oil (WEO). Our environmentally friendly process removes water, impurities, and additives without using sulfuric acid, producing stable, golden-colored diesel or base oil suitable for commercial sale.

- High Value Output:

The price of recycled Base Oil (SN150-SN300) is significantly higher than simple fuel oil. It can be blended into new lubricants or sold as hydraulic oil.

- Infinite Lifecycle:

Lube oil doesn’t wear out; it just gets dirty. By removing the contaminants (additives, metal shavings, carbon), you can use the oil again and again.

- Eco-Compliance:

Avoid illegal dumping penalties. Recycling is the only environmentally sustainable solution approved by governments worldwide.

Ruike Advanced Vacuum Distillation & Solvent Extraction System

The Ruike Advanced Vacuum Distillation & Solvent Extraction System represents a state-of-the-art solution for waste oil regeneration. Engineered for maximum efficiency and purity, this technology is designed to rigorously separate water, ash, and heavy metals from waste feedstock, delivering a high-yield output of premium-grade Base Oil or Diesel.

Key Performance Metrics

- High Recovery Rate: Achieves an industry-leading recovery rate of up to 85%.

- Versatile Output: Capable of producing high-quality Base Oil (Grades SN150–SN500) or Diesel fuel, depending on operational configuration.

- Contaminant Removal: Effectively eliminates impurities including water content, ash residues, and heavy metals to ensure the final product meets stringent quality standards.

Tailored Technology for Your Target Product

Different outputs require different refining processes. We provide specialized solutions for both.

Route A: Waste Oil to DIESEL (Fuel Focus)

Best for: Clients who want to sell fuel to burners, trucks, or power plants.-

Process: Pre-treatment -> Flash Distillation -> Gas-Phase Catalytic Refining.

-

Key Tech: Our Catalytic Tower cracks long chains slightly and removes sulfur instantly.

-

Output: High Quality Diesel (Flash Point > 60°C, Sulfur < 500ppm).

Route B: Waste Oil to BASE OIL (Lubricant Focus)

Best for: Clients who want to produce raw material for new lube oil blending.-

Process: Dehydration -> High Vacuum Distillation -> Solvent Extraction.

-

Key Tech: The Solvent Extraction Unit selectively dissolves and removes aromatics and gums. This improves the Viscosity Index and Oxidation Resistance.

-

Output: Base Oil (SN80, SN150, SN300) with stable golden color.

100% Eco-Friendly & Non-Acid Process

Strict environmental regulations are closing down old-school acid refineries. Ruike helps you stay compliant.

No Sulfuric Acid:

We use physical fractionation and solid catalysts, not liquid acid. No toxic acid sludge is produced.

Zero Air Pollution:

All non-condensable gases are recycled to the furnace for heating. Flue gas passes through our Desulfurization & Dust Removal Scrubber ensuring white/clear smoke emission.

Closed-Loop Water System:

Cooling water is circulated; no wastewater discharge.

Why Ruike Technology Wins

| Feature | Ruike Vacuum Distillation | Old Acid-Washing Technology |

|---|---|---|

| Process Type | Physical Re-refining (Vacuum + Catalysis) | Chemical Reaction (Sulfuric Acid) |

| By-Product | Dry Solid Residue (Can be used as fuel/asphalt) | Acid Sludge (Toxic, hard to dispose) |

| Oil Recovery Rate | High (85% – 90%) | Low (65% – 70%) |

| Oil Stability | High: Does not oxidize or change color. | Low: Turns black after 1-2 months. |

| Consumables | Low: Only catalyst and power. | High: Huge acid and clay consumption. |

| Worker Safety | Safe: Closed system. | Dangerous: Acid fumes and burns. |

Versatile Output for Maximum ROI

Our plant is engineered to produce high-value petrochemical products based on your market needs.

1. Industrial Diesel (80-85% Yield):

- Application: Heavy machinery, generators, burners, boilers, and agricultural vehicles.

- Specs: Flash point > 60°C, Sulfur content < 500ppm (with desulfurization), Light yellow color (0.5-1.5).

2. Base Oil (SN80 – SN300):

- Capable of recovering lube oil fractions for blending into new lubricants.

Ruike Advanced Waste Oil Regeneration System

Core Technology & Process

Flexible Solutions for High-Quality Base Oil & Diesel Recovery

The Ruike system is engineered for versatility and performance. Whether your target output is Group I Base Oil or High-Grade Diesel, our integrated vacuum distillation and refining technology delivers industry-leading yields (up to 85%) and exceptional purity.

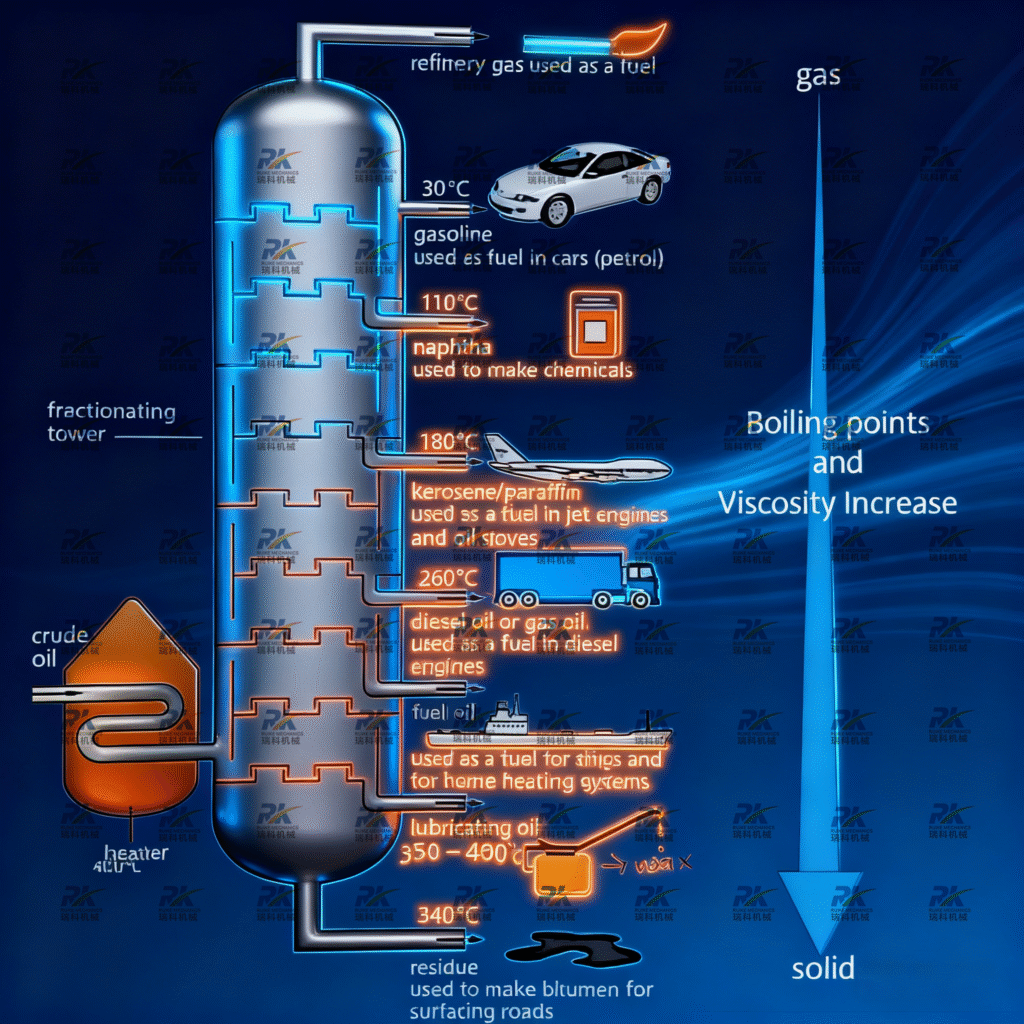

Process Flow: From Waste to Wealth: The Process

- Dehydration: Removing water content from collected waste oil.

- Flash Distillation: Separating light fuel components.

- Membrane Distillation / Rectification: Precise separation of diesel/base oil fractions under high vacuum.

- Catalytic Polishing: Improving color and removing sulfur smell.

- Filtration: Final cleaning for crystal-clear output.

Core Technology (Steps 1-2)

Standardized high-performance pre-treatment and distillation for all configurations.

1. High-Efficiency Pre-Treatment Thin Film Evaporator (WFE)

Wiped Film Evaporator (Optional/High-end): A scraping system that prevents oil from sticking to the wall, ensuring continuous heat transfer without fouling.

Operational Safety: Eliminates dangerous “bumping” and foaming in the main reactor, ensuring a stable, continuous feed for both diesel and base oil lines.

2. Precision Separation High Vacuum Distillation Tower

SS316L Structured Packing: Features premium internal packing and operates under deep vacuum (-0.098 MPa).

Low-Temperature Distillation: Distills oil at reduced temperatures to prevent thermal cracking, preserving the hydrocarbon chains for maximum quality.

Versatile Refining Configurations (Step 3)

Customizable modules based on your target product.

Solvent Extraction Tower for Base Oil Production Line

Function: A specialized Liquid-Liquid Extraction Column using counter-current flow.

Benefit: Selectively removes aromatics to upgrade distilled oil to Group I Standards, ensuring superior color and oxidation stability.

Solvent Recovery: Includes a closed-loop system that recycles >99% of the solvent, keeping operational costs extremely low.

Function: Optimized fractionation cuts specifically for diesel fuel properties.

Benefit: Produces clean, high-calorific value Diesel suitable for industrial use. The process effectively removes ash and heavy metals, delivering a clear, stable fuel product with a recovery rate of up to 85%.

Advanced Distillation & Polishing for Diesel Production Line

Automation & Control

Intelligent Operation: The entire plant is managed via a centralized DCS (Distributed Control System) or PLC (Programmable Logic Controller).

Precision Monitoring: Ensures real-time monitoring of temperature, pressure, and flow rates, guaranteeing safety and consistent product quality with minimal manual intervention.

Get A technical Proposal

System Specifications

| Feature | Base Oil Configuration | Diesel Configuration |

|---|---|---|

| Primary Technology | Vacuum Distillation + Solvent Extraction | Vacuum Distillation + Fractionation |

| Vacuum Pressure | -0.098 MPa | -0.098 MPa |

| Key Component | SS316L Packing / Extraction Tower | SS316L Packing / Polishing System |

| Output Quality | Group I Base Oil (SN150-SN500) | High-Quality Industrial Diesel |

| Recovery Rate | High Yield Optimization | Up to 85% |

Customized Project

Start Your Lube Oil Recycling Plant

send us your waste oil type and daily capacity.

Why Not Acid Washing?

No Acid, No Sludge

Traditional Acid-Clay technology is banned in many countries. We offer the green alternative.

Feature | Ruike Solvent/ Vacuum Process | Old Acid-Washing Method |

Chemicals Used | Recyclable Solvent / Catalyst | Strong Acid (H2SO4) |

Pollution | Zero (Closed loop) | Hazardous Acid Sludge |

Oil Yield | High (85%) | Low (70% – loss to sludge) |

Quality Stability | High (Stable for months) | Low (Turns black in weeks) |

Precision Control for Dangerous Goods

Refining involves high temperature and flammable gas. Safety is engineered into every step.

Precise Temperature Control (PID):

Our PLC system uses PID Logic to regulate heating within ±1°C. This precision is critical for separating specific oil grades.

Vacuum Safety Interlock:

Automatically cuts off heating if vacuum pressure drops, preventing oxygen ingress and fire risks.

Explosion-Proof Design:

All motors, pumps, and electrical cabinets are Ex-proof Standard for hazardous zones.

Frequently Asked Questions

Q1: Why do I need Solvent Refining for Base Oil?

Simple distillation removes dirt but leaves chemical impurities like aromatics. Without solvent refining, base oil will oxidize and turn black quickly. Solvent Extraction is the only way to produce stable, high-quality base oil.

Q2: Can I produce both Diesel and Base Oil with one machine?

Partially. The front-end (Distillation) is the same. However, the back-end is different (Catalytic for Diesel vs Solvent for Base Oil). If you want both, we can design a Hybrid System with switchable post-treatment lines.

Q3: Can I get Group II Base Oil from this machine?

Our technology produces high-quality Group I / Group I+ Base Oil.

It has excellent color (Water White) and Viscosity Index.

However, to reach strict Group II standards (Saturates >90%, Sulfur <0.03%), you would typically need a high-pressure Hydro-treating unit. For most recycling applications (blending standard lubricants), our Group I+ output is more than sufficient and highly profitable.

Q4: What about the Sulfur content in the Diesel produced from engine oil?

Waste engine oil generally contains less sulfur than tire oil. With our catalytic refining, the diesel output typically meets Euro III or Euro IV sulfur standards easily. It is much cleaner than pyrolysis diesel and safe for most engines without complex deep-desulfurization.

Q5: Is the solvent expensive? Is it consumed?

The solvent is initially expensive, but our system includes a Solvent Recovery Unit that recycles >99% of it. The daily consumption is negligible, making the operating cost very low.

Q6: What is the residue left over?

The remaining 10-15% is a heavy semi-solid residue (similar to asphalt/bitumen). It can be sold to asphalt plants or used as heavy fuel for waterproofing materials. It is not hazardous acid sludge.

Q7: Can I use the recycled base oil directly in cars?

No. It is a raw material. You need to blend it with additives (detergents, dispersants, etc.) to make finished motor oil (like 15W40). We also supply Lube Oil Blending Machines if you wish to start a blending business.

Will the oil turn black again after a few weeks?

No. Unlike acid-washed oil, Ruike’s distilled oil is chemically stable. Our proprietary Gas-Phase Catalysis technology removes the unsaturated hydrocarbons that cause color reversion, ensuring your product stays golden.

How much land do I need?

A standard 100TPD plant requires approximately 300-500 sqm. We provide full 3D layout drawings to fit your existing site.

Recommended Complementary Equipment

From single components to complete turn-key refineries, Ruike provides integrated engineering support to ensure all equipment works at peak performance.

Pyrolysis Machine

Converts waste tires, plastics, and rubber into fuel oil, carbon black, and steel wire through high-temperature thermal decomposition in an oxygen-free environment.

Oil Distillation Plant

Further refines tire oil, plastic oil, or used motor oil into high-quality diesel or gasoline fractions through fractional distillation and catalyst processing.

Pressure Vessels & Storage Tanks

Specialized containers designed to hold liquids or gases at pressures substantially different from the ambient pressure, fully compliant with ASME Boiler and Pressure Vessel Code.

Shell and Tube Heat Exchangers

Beyond condensation, these units are used for liquid-to-liquid heating or cooling and as reboilers in distillation processes.