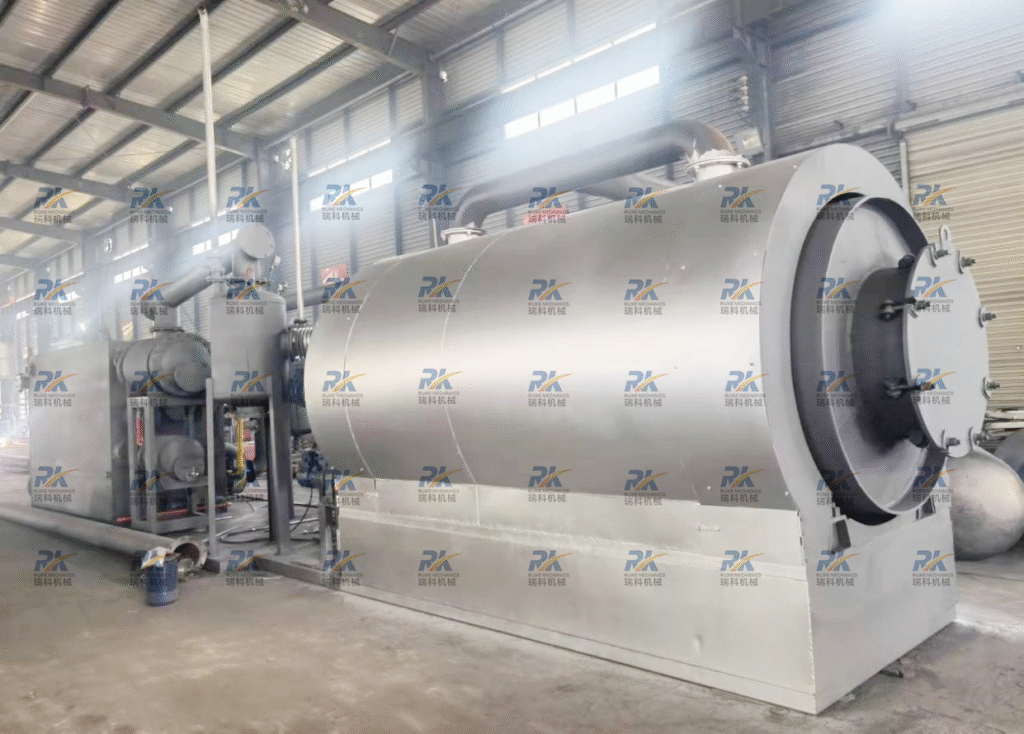

Skid-Mounted Pyrolysis Plant: The "Plug & Play" Solution

No installation. No civil foundation. The fastest way to start your waste-to-energy business. Pre-assembled on a steel base for maximum mobility and convenience.

Maximum Convenience in a Mini Package

A Skid-Mounted Pyrolysis Plant puts all the essential components—reactor, cooling system, condenser, and purification system—onto a integrated steel frame base.

Unlike traditional plants that require months of on-site construction, this unit is built and assembled in our factory. When it arrives at your site, you simply connect the water and electricity, and start production immediately.

Key Specs

- Capacity: 1 Ton - 3 Tons / Day

- Installation: 95% Pre-installed (Ready to run)

- Transport: Fits in one 40HQ Container

Ideal Applications

Pilot Projects / Feasibility Testing:

Perfect for investors who want to test the local market or raw material oil yield before investing millions in a large plant.

High Labor Cost Regions (USA/Europe):

Since no installation team is needed, you save tens of thousands of dollars in local engineering and labor costs.

Remote Areas & Islands:

Process waste directly at landfill sites or remote locations where building permanent infrastructure is difficult.

Laboratories & Universities:

For research on waste reduction and renewable energy.

Small Size, Industrial Standards

Don't let the size fool you. It packs Ruike's full industrial technology.

- Installation-Free (Plug & Play):

We complete piping, welding, and insulation at our factory. You save 20-30 days of installation time.

- Containerized Shipping:

The dimension is strictly designed to fit into a Standard 40ft High Cube Container (40HQ). Shipping is cheap and easy.

- Movable Asset:

Need to change your site? Just load the machine onto a truck and move it. Your investment is not stuck in the ground.

- Same Safety Standards:

Includes the same ASME standard reactor, Water Seal, and Pressure Safety Valves as our 50-ton industrial lines. Safety is never compromised.

Specifications

Model | Daily Capacity | Reactor Size | Cooling Method | Power Needed | Container Needed |

RKLJ-1 (Mini) | 1 Ton / Batch | 1.4m * 2.3m | Integrated Water Tank | 5 kW | 1 * 20GP or LCL |

RKLJ-3 (Mobile) | 3 Tons / Batch | 1.8m * 2.6m | Integrated Water Tank | 8 kW | 1 * 40HQ |

Low Running Cost: Water & Power Consumption

Designed for energy efficiency. Minimal utility requirements for easy deployment.

Ruike Skid-mounted units are engineered to operate with low energy inputs. Here is the estimated consumption data per batch.

Consumption Data Table (Per Batch Cycle)

Item | RKLJ-1 (1 Ton Capacity) | RKLJ-3 (3 Ton Capacity) | Notes |

Installed Power | 5 kW | 8.5 kW | Total power of motors & pumps. |

Actual Power Consumed | ~25 – 30 kWh / Batch | ~40 – 50 kWh / Batch | Motors do not run 100% of the time. |

Water (Circulating) | 3 m³ (Initial filling) | 5 m³ (Initial filling) | Zero consumption. Water is recycled in the integrated tank. Only minimal evaporation loss needs top-up. |

Fuel (Heating) | ~30-40 kg Diesel / Batch | ~80-100 kg Diesel / Batch | Or use 80-100m³ Natural Gas. Once tail gas is produced (after ~2 hours), fuel consumption drops to zero. |

Land Area Needed | 10 m² | 25 m² | Flat concrete ground required. |

Note: Fuel consumption varies based on the raw material’s moisture content and local temperature.

Customized Project

Start Your Recycling Business Today with Low Risk

Get the price list for our 1T and 3T Skid-mounted units.

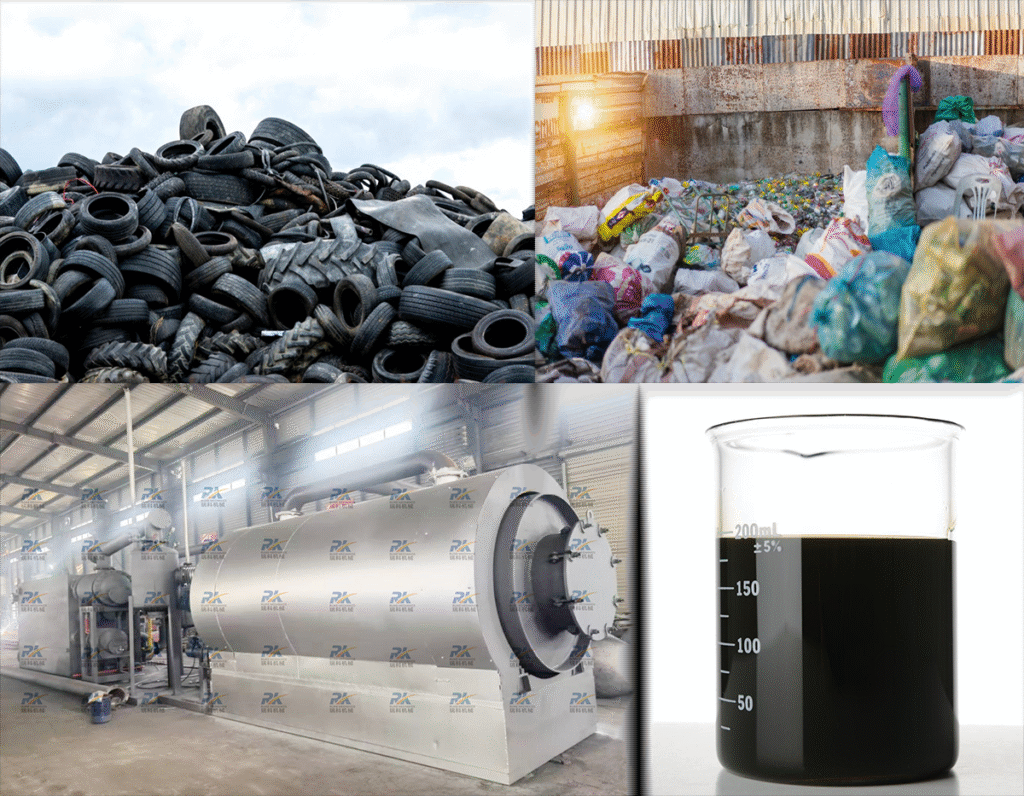

Profitable on a Small Scale

Even a mini machine generates daily revenue.

- Input: 1-3 Tons of Waste Tires/Plastics.

- Output:

- Fuel Oil: 45% – 50% (Sell to local boilers/farms).

- Carbon Black: 30% – 35% (Sell as solid fuel).

- Steel Wire: 15% (Sell as scrap metal).

- ROI:

Due to the low machine cost and zero installation cost, most clients break even in 3-6 months.

FAQ (Skid-Mounted Specific)

Q1: Do I need to build a concrete foundation?

No. You just need a flat, hardened ground (concrete floor) to place the skid. No digging or civil engineering required.

Q2: Does it produce smoke?

No. Despite its small size, it includes a compact Dedusting System and Tail Gas Recycling System. It is eco-friendly and odorless.

Q3: Can I expand the capacity later?

The skid unit is fixed capacity. If you need to expand, you can either buy a second skid unit or upgrade to our standard [Batch Pyrolysis Plant] (5T-15T).

Q4: What is the shipping cost?

Because it fits in a standard container, the ocean freight is very low compared to bulk cargo. Contact us for a precise freight quote to your port.

Recommended Complementary Equipment

From single components to complete turn-key refineries, Ruike provides integrated engineering support to ensure all equipment works at peak performance.

Pyrolysis Machine

Converts waste tires, plastics, and rubber into fuel oil, carbon black, and steel wire through high-temperature thermal decomposition in an oxygen-free environment.

Oil Distillation Plant

Further refines tire oil, plastic oil, or used motor oil into high-quality diesel or gasoline fractions through fractional distillation and catalyst processing.

Pressure Vessels & Storage Tanks

Specialized containers designed to hold liquids or gases at pressures substantially different from the ambient pressure, fully compliant with ASME Boiler and Pressure Vessel Code.

Shell and Tube Heat Exchangers

Beyond condensation, these units are used for liquid-to-liquid heating or cooling and as reboilers in distillation processes.