Advanced Atmospheric & Vacuum Distillation Plants for Waste Oil Refining

Turn Waste Engine Oil, Pyrolysis Oil, and Crude Oil into High-Grade Diesel & Base Oil.

Ruike Distillation Machine

Ruike has done many Distillation projects around the world

50Tons used engine oil distillation plant in America

3 Tons of waste plastic pyrolysis to diesel plant in UK

1 Ton Skid-mounted waste tire into diesel plant in US

50 Tons crude oil refinery plant in Myanmar

200 Tons used oil distillation to base oil plant in Uzbekistan

20 Tons crude oil distillation machine in Iraq

150 Tons used oil distillation to diesel plant in Indonesia.

100 Tons Naphtha converts into 93 gasoline project in Bangladesh.

200TPD distillation plant for used oil purify into diesel and gasoline in Singarpore

And More…

One Technology, Multiple Applications

We provide specialized refining solutions for different raw materials.

Engineer highly efficient refineries with Ruike’s ASME-certified rectification technology. We deliver end-to-end solutions—from engineering design (EPC) to on-site commissioning—helping you achieve 85%+ recovery rates and Euro-standard diesel quality.

- 1. Used Engine Oil (Lube Oil): From cars, trucks, ships.

- Target Output: Base Oil (Lubricant raw material) or Diesel.

- Yield: 80% – 85%.

- 2. Crude Oil & Pyrolysis Oil: Raw crude from oil fields or heavy tire oil from pyrolysis plants.

- Target Output: Gasoline, Kerosene, Diesel.

- Yield: 85% – 90%.

Precision Fractionation Technology

Don’t settle for simple boiling. Ruike’s Atmospheric and Vacuum Rectification process is a true petrochemical refining standard tailored for waste recycling.

Unlike traditional “pot distillation” which produces dark, unstable oil, our multi-stage fractionation system separates light and heavy components with molecular precision.

- Feedstock Flexibility: Handles Waste Engine Oil (WEO), Tire/Plastic Pyrolysis Oil, Crude Oil, and Sludge Oil.

- Premium Output: Produces Water-white Diesel, Gasoline, Naphtha, and Base Oil (SN150/SN300).

- High Yield: Up to 90% recovery rate (depending on feedstock) with proprietary thin-film evaporation.

Select Your Refining Plant

Ruike distillation machines utilize high-end technology.

We have developed the technology for thin film, atmospheric, and vacuum distillation towers with catalysts, as well as a further refining system. With PLC or DCS control system.

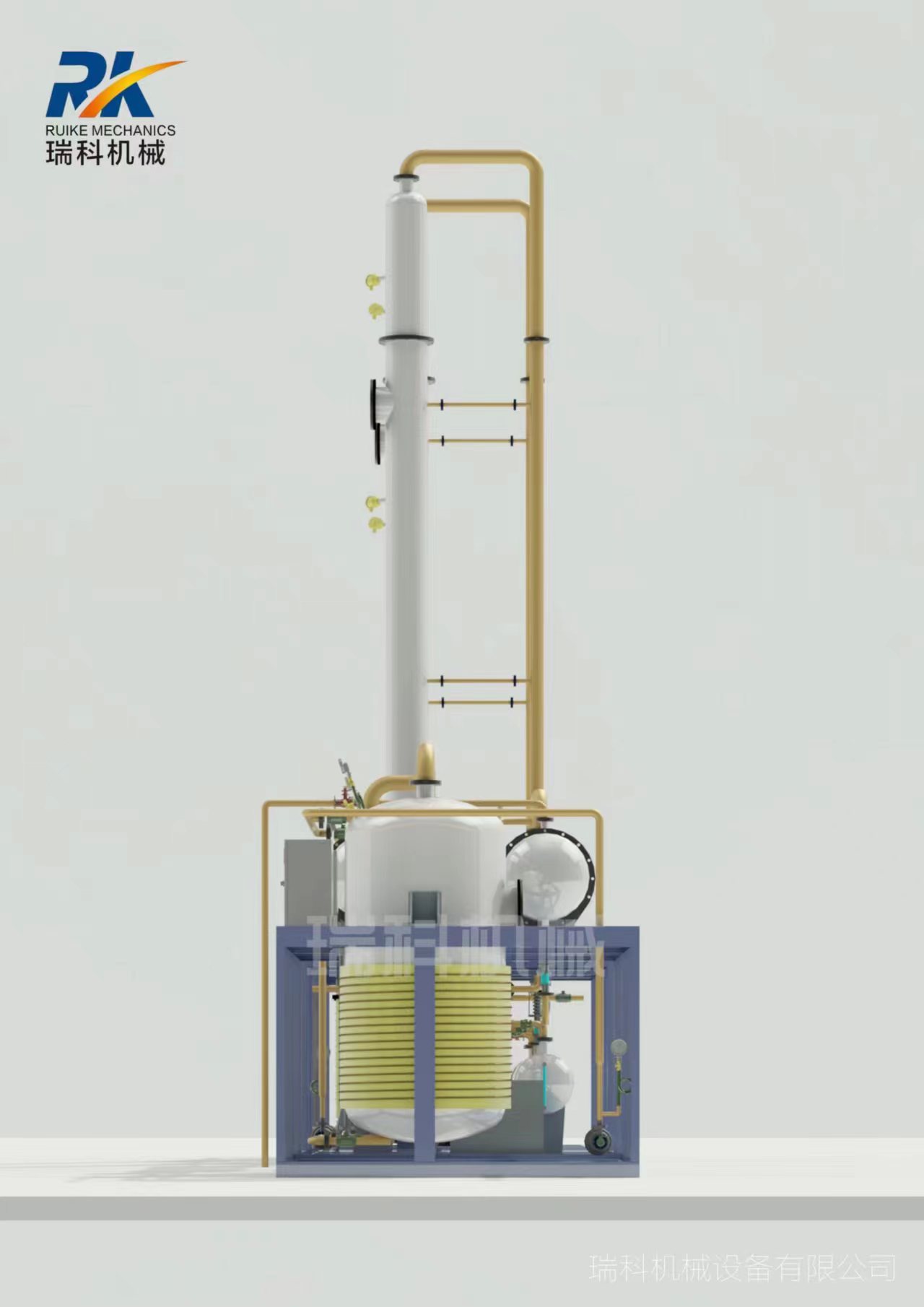

Solution A: Used Engine Oil Recycling Plant

Best for: Recycling centers, waste management companies.

Focus: Dehydration, Ash Removal, Bleaching. Restoring oil purity from dirty lube oil.

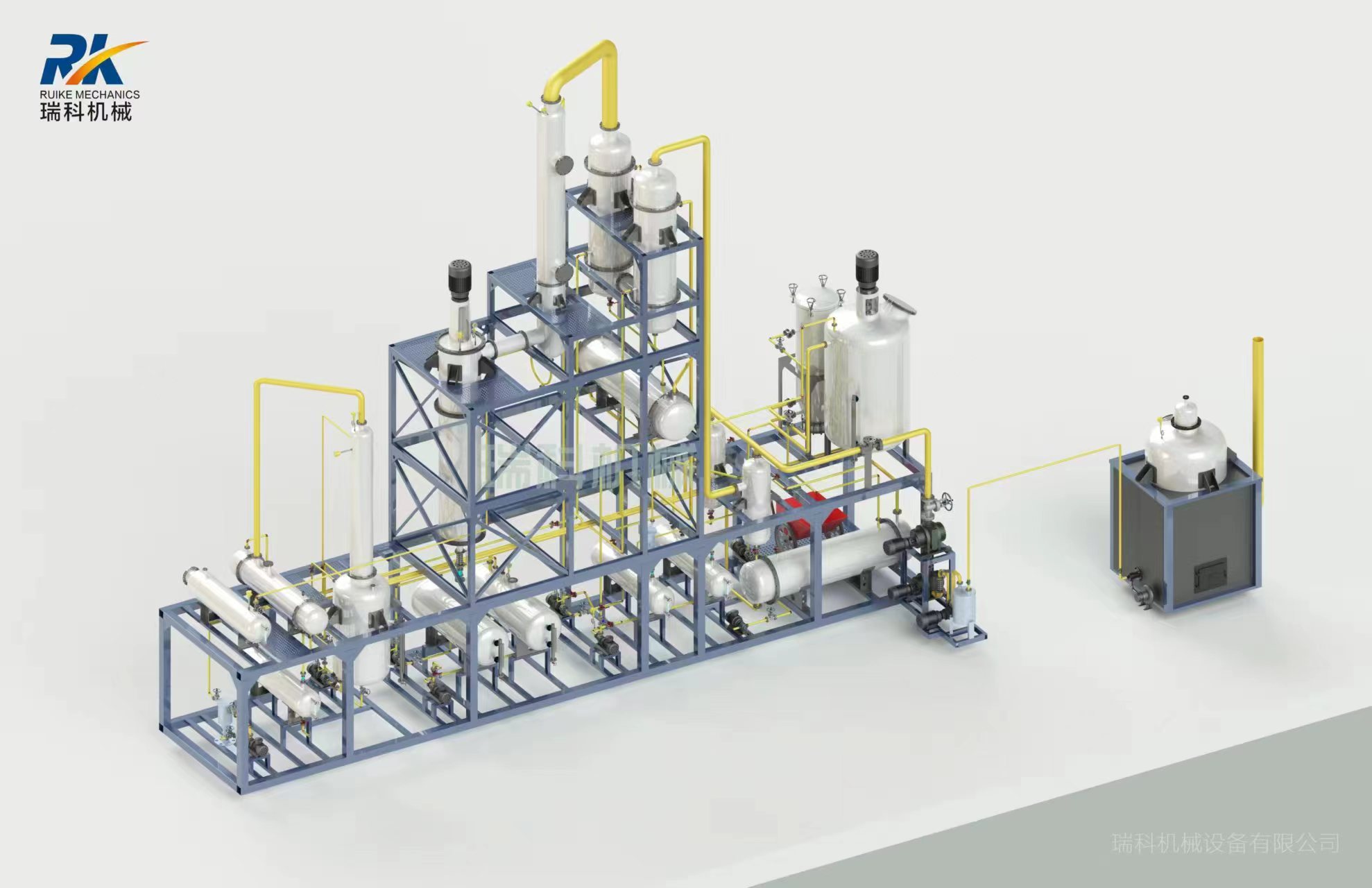

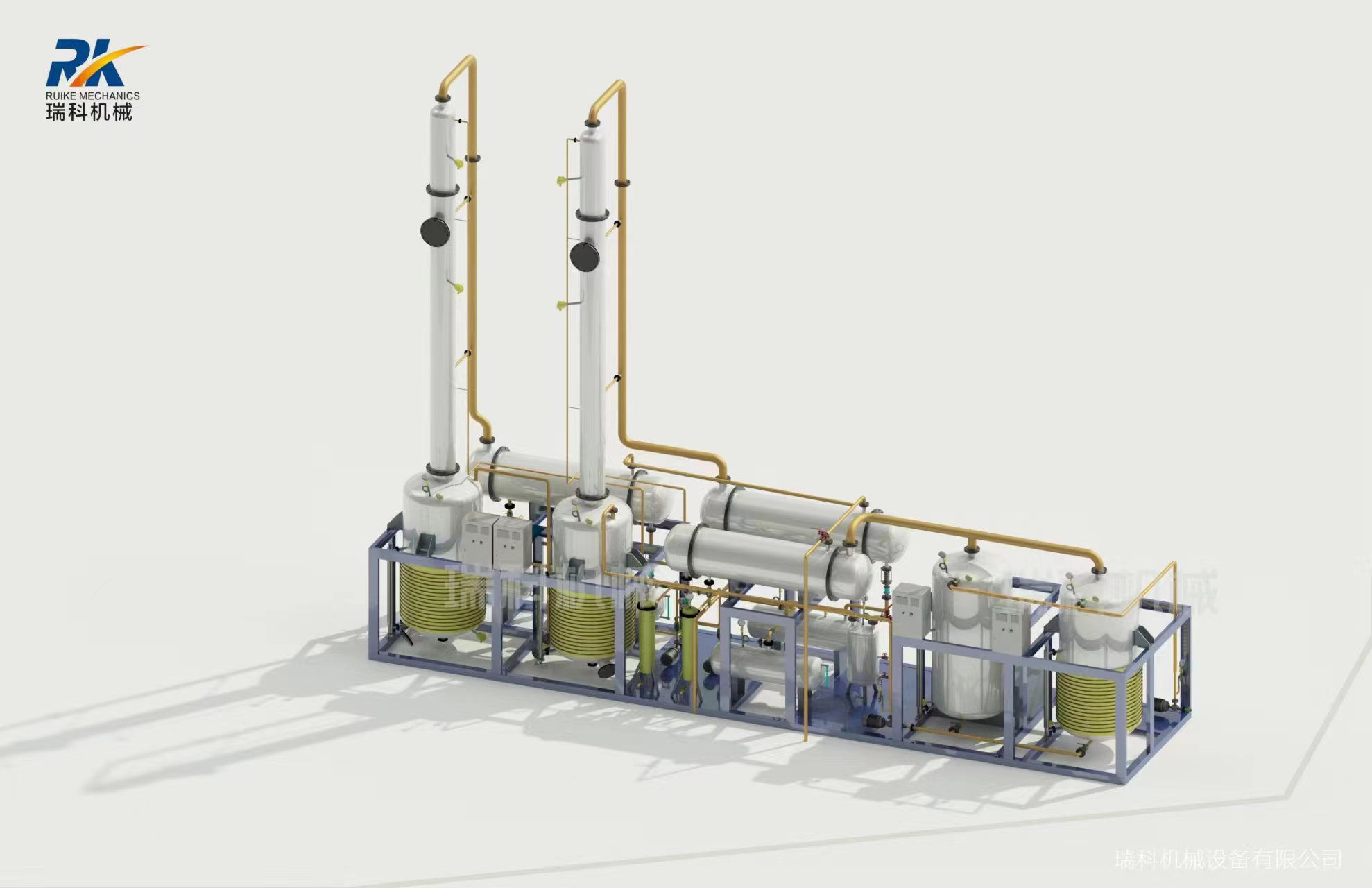

Solution B: Crude/Pyrolysis Oil Refinery

Best for: Mini-middle capacity refineries, Pyrolysis plant owners.

Focus: Precise Fractionation of light/heavy components; Desulfurization; Odor Removal.

Professional Refinery Process: Atmospheric & Vacuum Rectification

Moving beyond simple distillation. We bring petrochemical refinery standards to waste recycling.

Vacuum Distillation (Low Temp, High Quality):

Ruike utilizes a powerful High Vacuum System to lower the oil’s boiling point.

Benefit: Oil that boils at 350°C normally will boil at only 200°C.

Result: Prevents oil cracking (no bad smell), ensures lighter color, and saves 30% heating energy.

Rectification Tower (Precise Separation):

We employ a Packed Column Rectification Tower. Inside, rising vapor and falling liquid reflux contact repeatedly.

Result: This precisely separates light components from heavy impurities, ensuring high flash point and pure composition.

Gas-Phase Catalytic Technology:

Our proprietary tower uses a special catalyst to treat oil gas while it is hot. It removes sulfur and odor instantly. No acid, no alkali, no clay needed.

Atmospheric & Vacuum Distillation vs. Pot Distillation

Ruike Vacuum Rectification System

The Petrochemical Refinery Standard.-

Technology: Continuous/Semi-Continuous with Fractionation Column

-

Heating Method: Indirect Heating (Molten Salt/Thermal Oil)

-

Efficiency High Yield: Extracts all light fractions. Energy saving.

-

Oil Quality: Euro-Standard Diesel: Golden color, stable, high flash point.

-

Precise Cuts: Rectification tower separates gasoline and diesel, ensuring safe flash points for each.

-

Safety High: PLC Control, Vacuum Breakers, auto-relief valves.

Traditional : Kettle Distillation

Also known as "Simple Kettle" or "Batch Distillation"-

Technology: Simple Batch Boiling (Kettle type)

-

Heating Method: Direct Fire (Coal/Wood/Gas)

-

Low Quality: High temperature causes oil cracking. The diesel comes out dark, smelly, and unstable (turns black in days).

-

Low Yield: Cannot extract heavy components effectively; residue is high.

-

Oil Quality: Low Grade: Dark red/black, bad smell, oxidizes quickly:

-

No Separation: Gasoline and Diesel are mixed together. Flash point is dangerously low.

-

Safety Low: Risk of fire/explosion due to uneven heating.

Comparison Table

Feature | Ruike Vacuum Distillation | Traditional Pot Distillation |

Heating Method | Indirect (Molten Salt / Thermal Oil) | Direct Fire (Coal/Wood) |

Boiling Point | Reduced by Vacuum (~200°C) | High (~350°C+) |

Oil Color | Water White / Golden | Dark Red / Black |

Oil Smell | Clean (No cracking smell) | Strong Pungent Smell |

Safety Level | High (Auto-controlled) | Low (Manual operation) |

Continuous Running | Yes (Possible) | No (Batch only) |

Custom-Built to Your Capacity

From pilot testing to commercial refining, we design the plant to fit your site and budget.

Skid-Mounted Units (1T – 10T/day): Plug-and-play design for small recyclers or pilot projects. Easy shipping in a 40HQ container.

Industrial Plants (20T – 300T/day): Full-scale refineries with continuous operation capability, DCS control rooms, and large storage tank farms.

Premium Components for Industrial Refining

We don’t cut corners. Ruike integrates top-tier petrochemical components to ensure safety, efficiency, and precise separation.

Wiped Film Evaporator (WFE-Efficient Dehydration)

Function: Before distillation, waste oil often contains water. Our TFE creates a microscopic film of oil on the heated wall, instantly flashing off water and light gases.

The Advantage: It prevents the dangerous “bumping” (oil splashing) and foaming inside the main reactor, ensuring the system runs smoothly and safely.

Molten Salt Heating System (High-Temp Power)

Function: Unlike standard thermal oil (which degrades above 300°C), our Molten Salt System can safely reach temperatures up to 450°C – 500°C.

The Advantage: This high heat is critical for deep distillation of heavy crude or sludge oil, allowing you to extract the very last drop of diesel from the residue without using dangerous direct fire.

Negative Pressure (Vacuum) Distillation Tower

Function: Operates under high vacuum (-0.09Mpa to -0.098Mpa).

The Advantage: It drastically lowers the boiling point of the oil. This “Low-Temperature Distillation” prevents the oil from cracking (which causes bad smell and dark color) and reduces energy consumption by 30%.

Rectification Tower (Precise Separation)

Function: Filled with structured packing and stainless steel trays. It forces the rising vapor to contact with liquid reflux multiple times.

The Advantage: This process precisely cuts the oil mixture into distinct fractions: Gasoline, Kerosene, and Diesel. Without this tower, you only get mixed oil; with it, you get commercial-grade products.

Tubular Condensers (Shell & Tube Type)

Function: We use industrial standard Shell-and-Tube Heat Exchangers rather than simple pipe coils.

The Advantage:

- High Efficiency: Maximizes the heat exchange surface area to ensure 100% of oil gas condenses into liquid.

- Easy Maintenance: The ends can be opened for easy cleaning of scale or blockage, ensuring long-term performance.

Precise Fractionation: Maximize Your Profit

One input, multiple high-value outputs.

Thanks to our temperature-controlled tower, we can cut the oil gas into specific products:

- Naphtha / Gasoline (< 180°C): Used as solvent oil or fuel blend.

- Kerosene (180°C - 240°C): Clean burning fuel.

- Standard Diesel (240°C - 350°C): Golden color, high flash point. The main profit product.

- Heavy Residue / Asphalt (> 350°C): Used for waterproofing or road paving.

EPC & Site Services

Complete On-Site Technical Support

Refinery projects are complex. Ruike provides end-to-end support to ensure your plant operates successfully.

Professional Installation Team:

We dispatch senior engineers (mechanical & electrical) to your site. They oversee the unloading, positioning, piping assembly, and wiring according to the P&ID design.

Commissioning & Start-up:

Installation is just the start. Our experts will stay to conduct the Cold Test (pressure test) and Hot Test (feeding oil). We fine-tune the temperature and vacuum parameters until the output oil meets the target quality (Color/Flash point).

Operator Training (Knowledge Transfer):

We teach your local workers:

How to operate the PLC/DCS system.

How to control the Rectification Tower temperatures.

Safety protocols and emergency handling.

We don’t leave until your team can run the plant independently.

Long-term Technical Guidance:

Even after we leave, we provide lifetime remote support for:

Catalyst formula updates.

Process optimization consultation.

Spare parts supply.

Industrial Standard Manufacturing

- ASME Standard Vessels: We use 16mm-20mm Q345R Boiler Plate Steel. All welds undergo 100% X-Ray NDT and Hydrostatic Testing.

- Customized P&ID Design: We design the Piping and Instrument Diagram based on your specific oil analysis (Sulfur/Water content).

- Modular Construction: We pre-assemble the tower modules and piping skids in our factory, saving you 30% on installation time.

Send us your oil sample report. We will design the P&ID and calculate the yield for you.

More Than a Manufacturer – Your EPC Partner

We don’t just sell machines, we build operational businesses.

- Feasibility Analysis: Send us your oil sample; we provide a full lab report and yield calculation.

- Custom Engineering: P&ID diagrams, 3D plant layout, and foundation drawings tailored to your land.

- Global Installation: Our engineers fly to your site (78+ countries served) to guide installation, commissioning, and staff training.

Frequently Asked Questions

Process & Quality

What is the difference between simple distillation and Ruike's Rectification?

Simple distillation acts like a kettle, boiling everything together. Ruike’s Rectification uses a fractionating column to repeatedly condense and vaporize oil, precisely separating Diesel, Gasoline, and Naphtha based on boiling points. This results in far superior purity and commercial value.

Can I adjust the ratio of Gasoline and Diesel?

Yes. By adjusting the reflux ratio and top temperature of the tower, our engineers can help you maximize the output of the product you want (e.g., maximize Diesel yield) based on market demand.

How do you handle the non-condensable gas (smell)?

We use a Vacuum Jet System to extract these light gases. They are then scrubbed by a water seal and routed back to the furnace to burn as heating fuel. This eliminates the smell and saves energy.

Is the vacuum process safe?

Absolutely. Operating under vacuum is actually safer than high pressure. We equip the system with Pressure Safety Valves, Vacuum Breakers, and Nitrogen Purging systems to prevent any risk of implosion or explosion.

How often do I need to change the catalyst?

Our gas-phase catalyst is long-lasting. Typically, you only need to clean or regenerate it every 6-12 months depending on your raw oil quality. It is much cheaper than buying acid/alkali chemicals daily.

How often do I need to change the catalyst?

Our gas-phase catalyst is long-lasting. Typically, you only need to clean or regenerate it every 6-12 months depending on your raw oil quality. It is much cheaper than buying acid/alkali chemicals daily.

Can this plant process high-sulfur tire oil?

Yes. Our system integrates a Catalytic Tower and optional desulfurization units to reduce sulfur content, ensuring the final diesel meets environmental standards for industrial or vehicle use.

Do you provide installation services in my country?

Absolutely. Ruike has successfully installed projects in the USA, UK, Uzbekistan, Malaysia, and Indonesia. We provide turnkey installation and lifetime technical support.

Recommended Complementary Equipment

From single components to complete turn-key refineries, Ruike provides integrated engineering support to ensure all equipment works at peak performance.

Pyrolysis Machine

Converts waste tires, plastics, and rubber into fuel oil, carbon black, and steel wire through high-temperature thermal decomposition in an oxygen-free environment.

Pressure Vessels & Storage Tanks

Specialized containers designed to hold liquids or gases at pressures substantially different from the ambient pressure, fully compliant with ASME Boiler and Pressure Vessel Code.

Shell and Tube Heat Exchangers

Beyond condensation, these units are used for liquid-to-liquid heating or cooling and as reboilers in distillation processes.