Industrial Waste Pyrolysis Plants & Thermal Depolymerization Solutions

Turn Tires, Plastics, and Oil Sludge into Fuel Oil with High-Yield, Eco-Friendly Technology.

Ruike Pyrolysis Machine

Ruike has installed many sets of waste tire and plastic pyrolysis machines in Malaysia, Indonesia, India, Mexico, Turkey, Brazil, South Africa, Poland, and more than 78 other countries and regions.

Wide Range of Material Applicability

Transform Waste into Energy Efficiently

Ruike Petrochemical engineers advanced Pyrolysis Plants that utilize thermal decomposition to convert hydrocarbon waste into commercially valuable Fuel Oil, Carbon Black, and Combustible Gas.

Whether you are a municipal waste center or a private recycling investor, we offer tailored solutions ranging from Skid-Mounted Units to Fully Continuous Industrial Lines.

- Waste Tires: Car tires, truck tires, OTR tires (Avg. Oil Yield: 45%-50%).

- Waste Plastics: PP, PE, PS, ABS, Paper mill waste (Avg. Oil Yield: 30%-90%).

- Oil Sludge: Tank bottom sludge, drilling sludge, oil-soaked soil.

- Rubber Products: Cable skins, shoe soles, conveyor belts.

Profit from the Output

Turn waste into marketable commodities.

Pyrolysis Oil (Fuel Oil)

High calorific value (>10,000 kcal). Used in cement plants, steel mills, or refined into Diesel using our Crude Oil Distillation Machine

Carbon Black

Can be briquetted as fuel or refined (N330 standard) for making rubber products.

Steel Wire

Directly sold to steel smelting plants for recycling.

Combustible Gas

Recycled to heat the reactor, saving your fuel costs.

Select the Right Pyrolysis Plant for Your Business

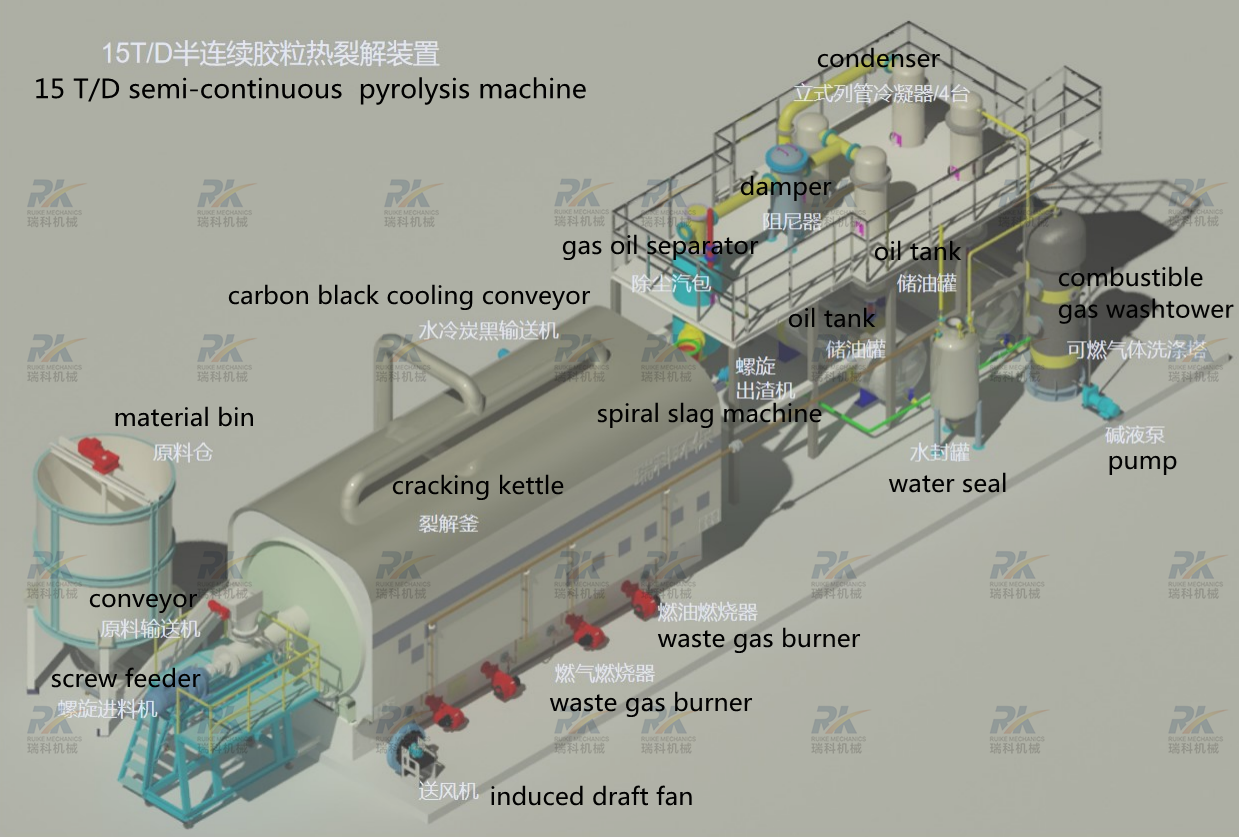

Batch Pyrolysis Plant

Best for: Start-ups, Limited Budget, Mixed Materials.

- Capacity: 1 Ton - 15 Tons / Day.

- Structure: Rotary Reactor.

- Features: Cost-effective; Handles whole tires directly; Easy maintenance.

- Popular Models: RLLJ-5 (5T), RLLJ-10 (10T), RLLJ-15 (15T).

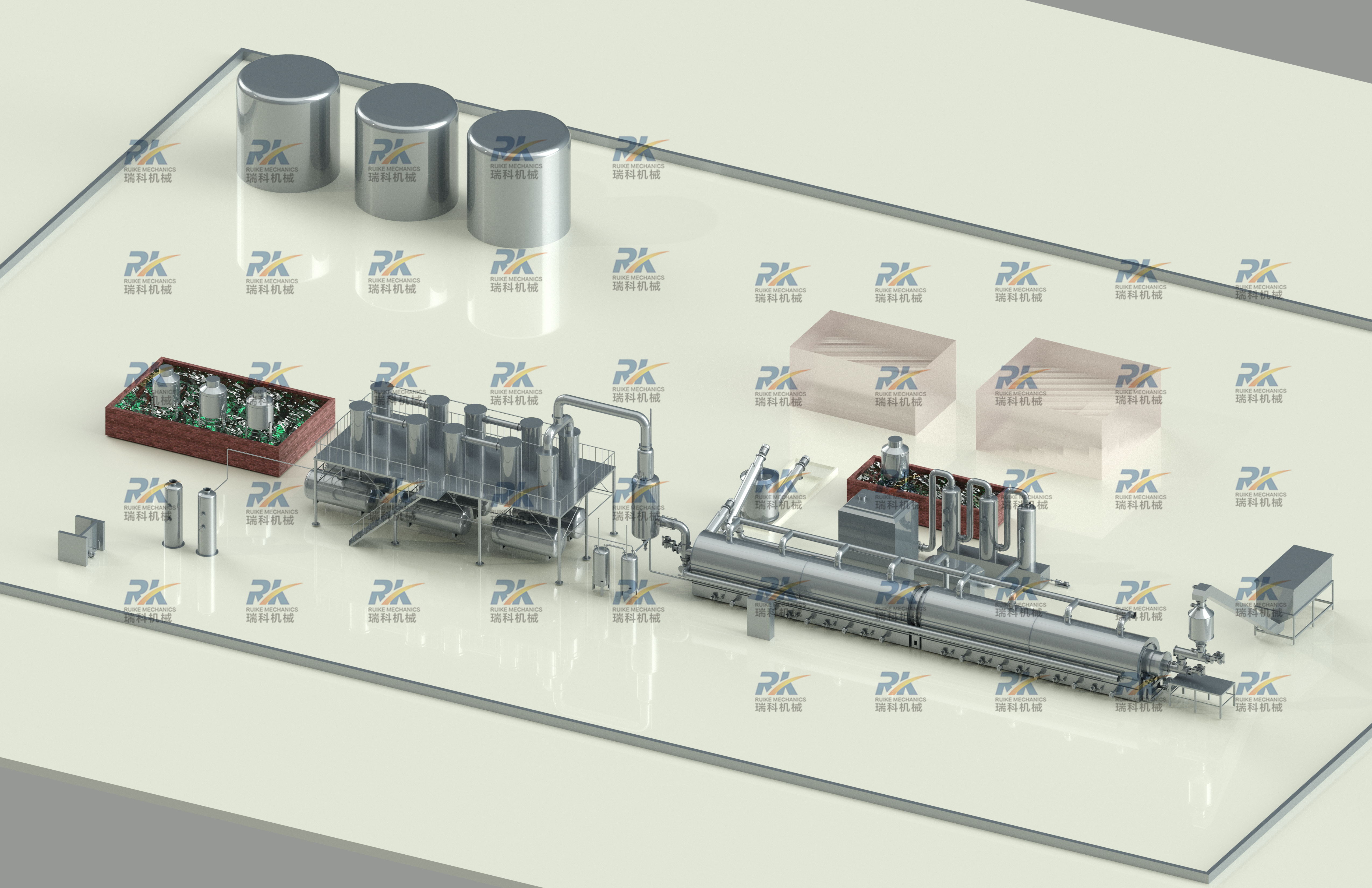

Fully Continuous Pyrolysis Plant

Best for: Large Scale Projects, High Labor Costs, and Strict Regulations.

- Capacity: 30 Tons - 50+ Tons / Day.

- Structure: Horizontal Fixed Reactor with Internal Screw.

- Features: 24/7 Non-stop running; Auto-feeding & Discharging; PLC Control.

- Popular Models: RKLXLJ-30 (30T), RKLXLJ-50 (50T).

Quick Comparison: Batch vs. Continuous

Feature | Batch Type Plant | Fully Continuous Plant |

Daily Capacity | 1T – 15T | 30T – 50T+ |

Working Mode | One batch/day (Heat-Cool-Discharge) | 24/7 Continuous Running |

Feed Material | Whole tires / Mixed plastics | Shredded tires (Rubber powder) / Crushed plastics |

Automation | Low / Medium | High (PLC/DCS Integration) |

Labor Needed | 3-4 Workers | 1-2 Workers |

Investment | Low | High |

See Our Machines in Action

Experience the Ruike quality through 3D demos and real site footage.

Customized Project

Explore your project plan

We offer you complete sample project budget, complimentary concept evaluation, cost analysis, layout, and more…

If you have any special requirements about your project, please contact Nancy, and we will offer you a customized project plan for you.

Built to Last: The Ruike Standard

Why 78+ countries choose Ruike over competitors? It’s in the details.

Manufacturing Excellence (Safety & Durability)

- ASME Standard Material:

We use 16mm-18mm Q345R Boiler Plate Steel specifically for high-pressure vessels, ensuring resistance to high heat (up to 600°C).

- Precision Welding:

We utilize Automated Submerged Arc Welding for reactor seams. Every weld undergoes 100% X-Ray Flaw Detection and Hydrostatic Testing to guarantee zero leakage risks.

- Curved Head Design:

Unlike flat heads, our curved reactor heads disperse pressure evenly, extending service life by 2-3 years.

Core Technology (High Yield & Eco-friendly)

- 3-Stage Cooling System:

Combining Vertical Tube Condensers, Horizontal Condensers, and Cooling Towers to maximize heat exchange area. Result: 5% higher oil yield than standard designs.

- Safety Interlocks:

Equipped with Vacuum devices, Water seals, and Auto-pressure relief valves to prevent backfire and over-pressure.

- Zero Emission:

Our 4-layer Dedusting System (Water spray + Ceramic ring adsorption + Desulfurization) ensures exhaust meets EU/US environmental standards.

Q1: What exactly is waste tire/plastic pyrolysis?

Pyrolysis is the thermal decomposition of carbon-based materials in an oxygen-free (anaerobic) atmosphere. In simple terms, we heat waste tires or plastics inside a sealed reactor to break their molecular bonds, converting them into Fuel Oil, Carbon Black, and Combustible Gas, without burning them.

Q2: What are the applications of the final products (Tire Oil & Carbon Black)?

The output has high economic value:

- Fuel Oil: Used directly in industrial factories (cement, glass, steel mills) or refined into diesel by our Distillation Machine.

- Carbon Black: Can be briquetted for burning or refined into N330 specification for making rubber products.

- Steel Wire: Sold directly to recycling stations.

Q3: Can I process mixed tires and plastics in the same batch?

Technically yes, but we recommend sorting them for the best oil quality and yield. Different plastics have different melting points and oil yields (e.g., PP/PE is high, PET is low). Our engineers can help you design a sorting and feeding plan based on your raw material sources.

Q4: Is the process environmentally friendly? Will it produce smoke?

Ruike plants are designed with a “Zero Emission” philosophy.

- Water: We use a circulating water cooling system; no contaminated water is discharged.

- Gas: Non-condensable gas is recycled to heat the reactor (saving energy).

- Smoke: Our advanced dedusting system removes sulfur and particles, ensuring the exhaust is white steam, compliant with EU/US/EPA standards.

Q5: How do I choose between Batch and Continuous plants?

It depends on your budget and labor costs.

- Choose Batch if you have a limited budget, lower labor costs, or want to start small (1-15 tons/day).

- Choose Continuous if you handle massive amounts of waste (30+ tons/day), have high local labor costs, and need 24/7 automated operation.

Recommended Complementary Equipment

From single components to complete turn-key refineries, Ruike provides integrated engineering support to ensure all equipment works at peak performance.

Oil Distillation Plant

Further refines tire oil, plastic oil, or used motor oil into high-quality diesel or gasoline fractions through fractional distillation and catalyst processing.

Pressure Vessels & Storage Tanks

Specialized containers designed to hold liquids or gases at pressures substantially different from the ambient pressure, fully compliant with ASME Boiler and Pressure Vessel Code.

Shell and Tube Heat Exchangers

Beyond condensation, these units are used for liquid-to-liquid heating or cooling and as reboilers in distillation processes.